MadtownChris

Cadet

- Joined

- Sep 16, 2013

- Messages

- 21

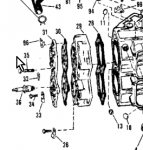

Hey all... I stupidly over tightened one of the cylinder head bolts in my 1978 85hp Evinrude - at least that's what I assume it is - one of the bolts that holds the whole water jacket and top of the cylinders on and I broke it off way down in there.

I took it to a local shop and it can't be removed and replaced without taking off the whole head.

They told me that they can't do it since they'd need a special alignment rig / jig or something like that. They directed me to a place that's about 8 hours away! And I'm really in boating central here in Wisconsin where I think the motor was built.

Do you have any advice? Should I call around to find a shop that would do it or would I end up with a bad repair without the specialized rig? I'd attempt it myself but it's a little advanced for my skills.

Thanks

Chris

I took it to a local shop and it can't be removed and replaced without taking off the whole head.

They told me that they can't do it since they'd need a special alignment rig / jig or something like that. They directed me to a place that's about 8 hours away! And I'm really in boating central here in Wisconsin where I think the motor was built.

Do you have any advice? Should I call around to find a shop that would do it or would I end up with a bad repair without the specialized rig? I'd attempt it myself but it's a little advanced for my skills.

Thanks

Chris