About Boat Trailer Tires

Proper size and load range is crucial when selecting new boat trailer tires, in order to match the proper load requirements of the trailer. The following characteristics are extremely important and should be thoroughly checked when replacing trailer tires. The following are the characteristics to look at closely:

- TIRE CONSTRUCTION TYPE -Bias Ply vs. Radial

- TIRE APPLICATION TYPE -(ST) Special Trailer vs. (P) Passenger Car

- TIRE SIZE -% of section height / section width Refereed to as 'Aspect Ratio'

- TIRE LOAD RANGE -Load carrying capacity and air pressure rating

- RIM SIZE -Diameter and width must match tire

- RIM BOLT CIRCLE -Diameter of bolt circle must match hub

There are three different identification systems that the trailer tire industry uses. All you need to do is look on the side wall of the tire you have to match up what you buy. The three systems are as follows:

- THE NUMERIC SYSTEM -(4.80 X 8) mostly used on smaller trailer tires, indicates the tire section width (4.80"), and the rim diameter (8")

- THE ALPHA NUMERIC SYSTEM -(B78 X 13 C) common on 13"-15" trailer tires, indicates air chamber size (B), the 'Aspect Ratio' (78), the rim diameter (13"), and the load range (C)

- THE METRIC SYSTEM -(ST205 75D 15) currently being phased in by trailer tire manufacturers, indicated the tire application type (ST-special trailer), the section width (205mm), the 'Aspect Ratio' (75), the construction type (D= bias ply), and rim dia.(15")

To make the tire work properly with your trailer, you also need the correct rim to go with that tire. Doing so will assure that your existing trailer hardware will work with the replacement tire and rim. Be certain to match the bolt pattern on the hub. It usually consists of either a 4 bolt or 5 bolt pattern.

You must also consider the maximum weight that each tire can support, or 'load range'. The load range and maximum weight capacity are indicated on the tire side wall.

- LOAD RANGE B = OLD 4 PLY RATING

- LOAD RANGE C = OLD 6 PLY RATING

- LOAD RANGE D = OLD 8 PLY RATING

Boat Trailer Tires How-Tos

Boat Trailer Tires 101

The fundamental elements of the tires are rubbers, fabric, and wire along with some compound chemicals. Main components for the tire are as follows:

TREAD - the main part of the tire that comes in contact with the road. The tread is thick rubber with grooves that run around the tire that are needed to channel away the water.

TREAD LUG - Tread lugs are what come in contact with the road to provide the traction. When in contact it compresses and reshapes, this creates Force Variation.

TREAD VOID - the voids provide space for flexing and deforming. It also provides the channels for water and other elements to be moved away from the “footprint".

RAIN GROOVE - is the design element of the tread that specifically arranged to channel water away. They run completely around the circumference of the tire.

SIPE - the smaller narrow voids the branch from the tread lugs. They improve the flexibility. It helps reduce shear stress and reduces heat build up.

WEAR BAR - indicators that are raised and located near the bottom of the tread grooves that the tire has reached the wear limit, letting you know it is time to change the tire.

BEAD - the part of the tire that comes in contact with the rim on the wheel. It is reinforced with steel wire and compounded high strength, low flexibility rubber.

SIDEWALL - the area between the tread and the bead. It is reinforced with fabric or steel cords that provides strength and flexibility.

SHOULDER - the part that transitions the tread to the sidewall.

PLY - layers of relatively inextensible cords embedded in the rubber to hold shape and prevent stretching.

Boat Trailer tires differ greatly from Automotive tires. Automotive tires are made to maintain traction through all conditions: pulling, stopping, turning, or swerving. For that reason they must have more flexible sidewalls to keep tread to road contact. The only time trailers need traction is when the trailer brakes are applied. With that in mind, you will want to decide on a tire style. You won't want to get (P) Passenger or (LT) Light Truck tires, but the best trailer control is achieved with (ST) Special Trailer tires.

Radial vs. Bias?

Bias, or cross, has the body ply cords that run diagonally from bead to bead. Usually at angle and with successive plies laying in a crisscross pattern. The crisscross pattern allows the body of the tire the flexibility to give a smooth ride on rough surfaces. Better for increased rolling resistance and less control and traction at higher speeds.

Radial construction utilizes the body ply cords extending from beads across the treads so they are at right angles to the center line of the treads. This ply uses stabilizer belts directly under the tread and are made of cord or steel. The advantage with this ply is longer tread life, better steering, and lower rolling resistance.

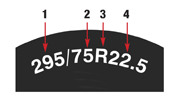

When it comes to choosing the replacement tire that you need, all you have to do is look at the tire you are replacing and all the information is there. ST225/75R15 or something similar is the number that you will be looking for.

ST - Special Tire

-this is the type of tire. Passenger (P), Light Truck (LT), or Special Tire (ST).

1 - Nominal width of the tire in millimeters (295)

2 - Ratio of height to width (75)

3 - Radial ( R ) or Bias ( B)

-this tells you what ply you would need

4 - Rim diameter code. (22.5)

After all this information, if you still feel like you have questions or need help, it is always bests to talk to the professionals. That is what they are there for. Good luck and happy tire hunting.

Everything You Ever Wanted to Know About Trailer Tires, But Were Afraid to Ask

Here is a great article that talks about everything you need to know about trailer tires.

Let me first off apologize to all of you who already know everything you ever wanted to know about trailer tires. Please skip to the next article immediately. However, for those of you needing a real page turner to fall asleep to every evening, please read on into night. Trailer tires and wheels may not be the most glamorous products produced by Kenda, but they are a significant part of our product line and are responsible for jobs at multiple location throughout the Kenda world.

Whenever trailer tires are discussed during a customer seminar the first thing we point out is that there are both leaders and followers in the world. The same applies to tires. Passenger car tires are the leaders in the tire kingdom with trailer tires being the followers. Passenger car tires are built with flexible sidewalls to handle turning and have treads designed for more traction and providing a smooth ride for the vehicle occupants. Trailer tires, both bias and radial products, have stiffer sidewalls to handle the stress and dynamics of towing. Sidewall flexing is a negative and the major cause of swaying during trailer operation. Trailer tires of identical size to the passenger car tire would have higher load carrying capacity due to the stiffer sidewalls and the overall design of the tire. If you were to use a passenger car tire for a trailer application you would immediately have to reduce the load rating inscribed on the sidewall of the tire by 11% due the tire construction differences.

Previously we mentioned both bias and radial boat trailer tires. The Kenda bias trailer tire is labeled Loadstar and our radial trailer tire is labeled the Karrier. While both carry the ST (Special Trailer) designation they are different in construction and suggested usage. A bias trailer tire is constructed with cords at a 32 degree angle and has a stiffer sidewall than our radial ST tires. More of the load of the tire is transferred to the center crown of the tire with less surface contact than the radial ST. It is more economically priced than our radial ST's and is great for rough terrain, weekend projects, and shorter trips. The radial ST has cords at a 90 degree angle providing more ground contact, a smoother ride, and, to some extent, better traction. More surface contact allows the heat to be dissipated over more area providing longer tread wear. While more costly than the bias, the radial tire is ideal for longer trips.

There are any number of good reasons that when it's time to purchase a trailer tire for your application the Kenda products are the right choice. Sure, it's great to support our company, but we have even better reasons to make the Kenda choice. Independent testing has shown that our bias trailer tires outwear our largest competitor's product 3 to 1. Recent testing has proved that our Karrier radial outperforms the Goodyear Marathon in puncture resistance and endurance. With a tire tread depth of 10/32" compared to the industry standard of 8/32" Kenda gives you more tire of the money. Our tire warranty is second to none in the industry. With our 800 customer service number on the sidewall of our trailer tires, should an issue arise, you can be sure that you will be provided with the assistance necessary to resolve your issue. Kenda is now offering a new program to the trailer manufacturing industry called “Kenda Care". When a customer purchases a new trailer with Kenda tires and also a Kenda spare from the dealer, you worries are over if you have a side of the road issue. “Kenda Care" provides you with an 800 number to call, a roadside assistance representative will come out and change your tire for you.

Congratulations, you are now the proud owner of an RV or trailer that has Kenda tires and Dexstar wheels. How should you take care of the tires and wheels that your precious load rest upon? Some suggestions that will provide a longer life and better performance from your Kenda tires and wheels:

- Check your tire pressures prior to going on every trip. Check tires when they are cold and inflate to maximum suggested PSI. If you must add air when your tires are hot, add 4 pounds PSI above the recommended cold air pressure. Recheck the inflation when the tire is cold.

- Maintain proper alignment of your tires. Like passenger car tires, poorly aligned tires wear more quickly.

- Visually inspect your tires for uneven wear, looking for high and low areas or unusually smooth areas.

- Don't overload your trailer. Both tires and wheels have load ratings, as does the axle on your trailer. Know the proper ratings and don't overload.

- When a trailer is in long-term storage put the trailer on blocks or jack stands under the axles to take weight off the tires. Lower the air pressure and keep your tires covered to protect them from the sun's ultra-violet light. If you can't put the trailer on blocks, park on a hard surface, like concrete or asphalt, not in your backyard.

- When a trailer comes out of storage inflate to the proper PSI and do a full tire inspection.

- Your Dexstar wheels also need maintenance. Regular cleaning to remove road soils can prevent trapped moisture from causing corrosion over a period of time. Treat the finish on your wheels like you would the finish on your car. Use the recommended wheel cleaning agents.

- If you have a new trailer be sure to retorque you lug nuts immediately after your first 25-50 miles, to insure proper fit. Anytime wheels are removed, retorque after 25-50 miles.

Proper tire and wheel care is important for your safety and the loads you are carrying. Take 5 minutes every month to check your tires and wheels, including the spare. Travel safely, have fun, and know that Kenda tires and wheels are there to support your journey.

Article courtesy of Joe Ostrowski