twintrades

Petty Officer 1st Class

- Joined

- May 7, 2008

- Messages

- 305

I like tashasdaddy idea of the transom jack but cant seem to find 3/8 aluminum.

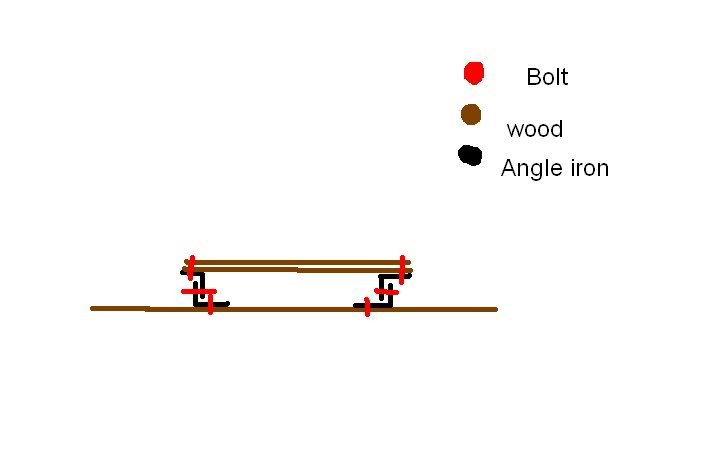

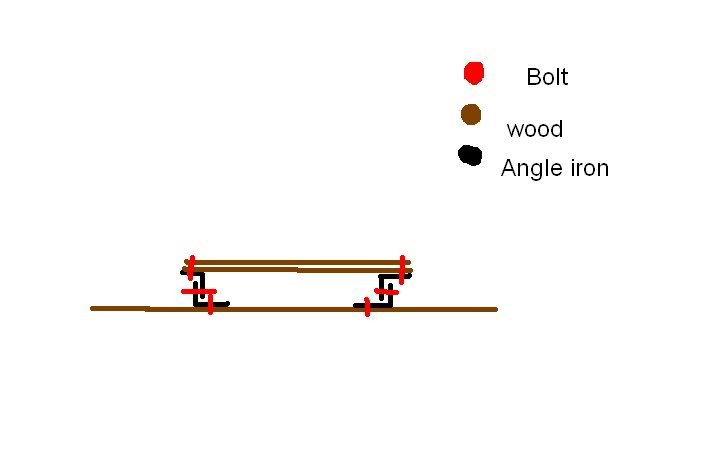

So i thought about using Steel or the thickest aluminim i can find in angel and bolting one to the transom then bolting the two together. And having the last peice of angle bolted to the pyl ( jacked transom). Two boltz top and bottom where ther needed.

Heres my idea

Would it put stress on the bolted joint and weeken it?? ( rather not loose my motor)

If i make it outa steel i would bolt it and weld it. ( new to welding to thats why the bolts.)

How far out should it stick? And are there any other benifits other that having the right motor hight?

So i thought about using Steel or the thickest aluminim i can find in angel and bolting one to the transom then bolting the two together. And having the last peice of angle bolted to the pyl ( jacked transom). Two boltz top and bottom where ther needed.

Heres my idea

Would it put stress on the bolted joint and weeken it?? ( rather not loose my motor)

If i make it outa steel i would bolt it and weld it. ( new to welding to thats why the bolts.)

How far out should it stick? And are there any other benifits other that having the right motor hight?