achris

More fish than mountain goat

- Joined

- May 19, 2004

- Messages

- 27,468

Quite a few people here have been rebuilding engines lately, and I thought having spent a lot of money on a rebuild they might like something to help protest their investment........ One of the hazards we can't really avoid completely is loss of water from the seawater pump in the drive, either by failure of the impeller, or picking up weed or a plastic bag. By the time the engine gets hot enough to notice, a lot of damage has already been done. One way to pick up that loss of water quickly is with a water pressure alarm.

--------------------------------------------------------------

Here?s how I would build a pressure alarm and gauge adaptor for a sterndrive?

I would start by making a manifold for the sensors.

Using a length of copper or stainless tube of the same diameter as the water hose between the transom plate and the thermostat housing (voltage regulator on a ?470?), make 3 ports, one each for the gauge, low pressure sensor and high pressure sensor.

For the gauge I would use a water pressure gauge (to match your current instrument cluster) from Merc, and I would install that first and get a look at the range of pressures you have. You?ll have the lowest pressure at idle when the engine is at normal operating temperature. Use that pressure as the lowest pressure. It?s going to be in the order of 1-5 psi. The highest pressure is going to be around 15-20 psi.

Once you have an accurate idea of the pressures that are ?normal? for your engine, order the sensors. I?ve done some research on the net and found these sensors. (but there are plenty of others around).

http://www.pryde.com.au/02_1.htm#switches Scroll down and look at MPL-500 series. They can be ordered to any pressure from 0.004psi to 20psi. They can also be configured for N/O or N/C electrical contacts. For the low pressure sensor you need Normally Closed (N/C), and for the high pressure you need Normally Open (N/O). What that will mean is that if the pressure is too low, the low sensor will be closed and the high sensor will be open, and if the pressure is too high, then the high sensor will close and the low pressure will be open. While the pressure is normal both switches will be open. The reason for the high pressure alarm is that as the exhaust elbow becomes older and clogs up the water pressure increases. That alarm will tell you when the elbow is becoming clogged and needs to be cleaned or replaced.

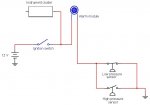

And this is the circuit for the alarm? You can use either the alarm module that Merc supply on there engines (I would recommend that one as it?s loud enough to hear above engine noise), part # -816492A6. If your engine already has an alarm system, it?s really easy. Just run the wires from the pressure sensors to the existing alarm harness, tie in anywhere at the low drive oil, low oil pressure or high engine temperature switches.

Cheers,

Chris..........

--------------------------------------------------------------

Here?s how I would build a pressure alarm and gauge adaptor for a sterndrive?

I would start by making a manifold for the sensors.

Using a length of copper or stainless tube of the same diameter as the water hose between the transom plate and the thermostat housing (voltage regulator on a ?470?), make 3 ports, one each for the gauge, low pressure sensor and high pressure sensor.

For the gauge I would use a water pressure gauge (to match your current instrument cluster) from Merc, and I would install that first and get a look at the range of pressures you have. You?ll have the lowest pressure at idle when the engine is at normal operating temperature. Use that pressure as the lowest pressure. It?s going to be in the order of 1-5 psi. The highest pressure is going to be around 15-20 psi.

Once you have an accurate idea of the pressures that are ?normal? for your engine, order the sensors. I?ve done some research on the net and found these sensors. (but there are plenty of others around).

http://www.pryde.com.au/02_1.htm#switches Scroll down and look at MPL-500 series. They can be ordered to any pressure from 0.004psi to 20psi. They can also be configured for N/O or N/C electrical contacts. For the low pressure sensor you need Normally Closed (N/C), and for the high pressure you need Normally Open (N/O). What that will mean is that if the pressure is too low, the low sensor will be closed and the high sensor will be open, and if the pressure is too high, then the high sensor will close and the low pressure will be open. While the pressure is normal both switches will be open. The reason for the high pressure alarm is that as the exhaust elbow becomes older and clogs up the water pressure increases. That alarm will tell you when the elbow is becoming clogged and needs to be cleaned or replaced.

And this is the circuit for the alarm? You can use either the alarm module that Merc supply on there engines (I would recommend that one as it?s loud enough to hear above engine noise), part # -816492A6. If your engine already has an alarm system, it?s really easy. Just run the wires from the pressure sensors to the existing alarm harness, tie in anywhere at the low drive oil, low oil pressure or high engine temperature switches.

Cheers,

Chris..........