Nice project Mr Lost. Zool does excellent epoxy work, your lucky to have him onboard!

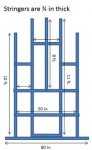

On the glass, I look at the average height of the stringers, use that plus the tabbing for a width. Then multiply that by the total linear footage of all the stringers and bulk heads to give me how many square feet I need I tack 20% on to that number.

So if I have one layer in the schedule with 4" tabbing, and the average stringer / bulkhead height is 4", then I figure the width is about 12" or a 1' Then if there is a total of 100' of stringers I would order 100' sf plus another 20sf for slop and waste. Based on that number, I figure out how many linear yards of cloth I need (depends on the width). I more or less do the transom, deck etc, the same way and breaking down each part and layer. There is probally a better way to estimate it, but that usually gets me close.

I order resin based on the type of glass, using the square footage, There are some ratios for poly that I use, but I don't know what they are for epoxy. I bet Zool can get you headed in the right direction,