srimshaw57

Recruit

- Joined

- Oct 12, 2015

- Messages

- 5

Purchase a 1987 Starcraft 221V Islander, transom has to be replaced. have read different thread on I boats.Have read epoxy some say glue I'm in a quandary as to how to proceed.

For an aluminum boat, I'd agree with using epoxy since the wood won't be encapsulated in fiberglass.

Is Cabosil a hardener? And where do you get the milled fibers? As you can see I'm new at this.

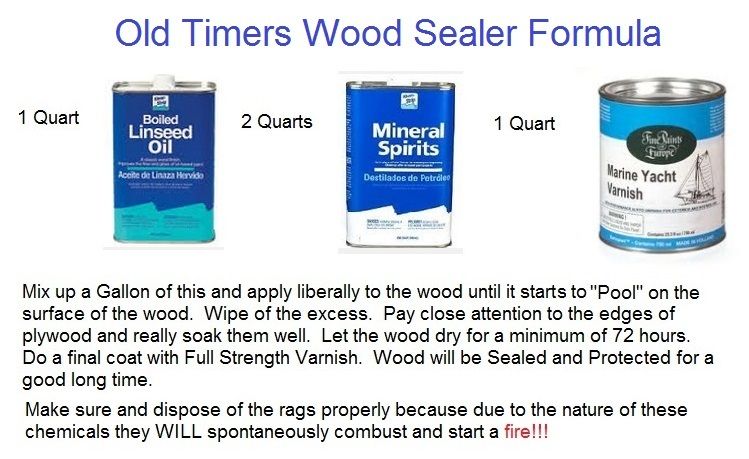

I think I'm going to go with titebond3 glue, I like the idea of not having to mix an epoxy and trying to get the right consistency and the right amount for the job.I would like to seal the transom before I install it. I don't know if I want to use linseed oil,or an oil based paint. Wanted to use pressure treated plywood for my flooring never thought about the chemical reaction.If it was sealed, paint or varnish first, would that be an option to eliminate chemical reaction?