Well let's see how much time I get.

Dave, you seem to be sure fuel isn't your problem --- I'm not.

Let me tell you where I'm coming from.

I've lost count of the times someone brought me a small runabout that didn't run right. Often they would tell how they or a different service provider had "pumped the tank empty" or "I added a lot of chemicals and good gas". At first I believed them. But I learned.

You tick quite a few boxes.

Transported fuel in gas cans to the boat.

Filled up at a sketchy marina.

Problem started right away or shortly after storage.

Engine computer is reporting 50% octane.

You're there and I'm not. Soooo

I looked at the pic you posted, That's a lot of crud for a filter with so little time on it. I assume it was replaced during winterization? The pic of the fuel needs to be a side view to tell anything. The bad stuff goes to the bottom.

I do know that adding ANY chemical to bad fuel can only make it worse, never better. Trying to dilute bad gas rarely works. The bad gas usually won't mix with good gas --- that's one of the things that make it bad gas.

The ONLY thing I would think about adding to gas is a good stabilizer before the boat is going to sit for more then 2-3 months

The only time I would add anything is if I had a D.I. engine like you have. I would use Chevron Techron Complete (or a comparable product that has been tested to the standards, I'm not aware of any others) if I wasn't able to fuel at least 1/2 the time at a Top Tier™ certified station.

https://www.toptiergas.com

Next up is --- bad fuel isn't covered under warranty. So if you do go to dealer and they find bad fuel. Lets just say you just gave them a license to charge whatever they want.

All this over one of the easiest and cheapest tests that you can do. Costs less then plugs, car and rotor that most dealers will want to start with. You already have everything you need except 4' of soft copper tubing.

I see that you feel "safe" continuing to use the boat. Not sure why you would think that? The boat is doing everything it can to tell you to stop using it and get it fixed. Once again I'm not there --- but the question isn't if your causing more damage (you are) the only question is how much damage. You have had cat damaging misfires in the past, you don't have cats to worry about. But they just call them cat damage misfires because the cat is the weakest link and goes bad first, doesn't mean they are the only thing that gets damaged. Do not take comfort that you don't see codes. The MIL light and warning horn tell me you do. you just haven't found the right conditions to log them.

Here is what I recommend you do next.

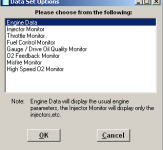

Clear the codes with Diacom, do this before you start the engine, once complete, shut everything off including the battery switch and wait 2 minutes, power everything back up and check that all codes are gone. Next before starting the engine, clear the misfire counters with Diacom.

IMPORTANT: do NOT clear the Misfire adaptive memory that you will find in this area ONLY the counters. We will do adaptive memory once the engine is fixed.

Yes Diacom is a steep learning curve and requires knowledge of how all the engine systems work I first started with Diacom back in the MEFI days and those ECMs were pretty simple, still took me many many hours and hours to learn enough to make the job easier.

I try to carry a moving blanket to put over my head and laptop screen to cut down on the sun glare or I'll use a customer beach towel (as long as it doesn't smell too much!)

What I would like, is for it to take you 3-4 minutes to get to full throttle, hold it for 30-60 seconds and then 3-4 minutes to get back to idle. Ski start to full RPMs and hold for 30-60 seconds, back to idle keeping an eye on the stern wave. The big thing is for each recording to be as consistent as the others. Patience is a trait that all good troubleshooters have.

The picture of the plug is from the wrong angle and reading plugs on a computer monitor isn't best.

No I haven't seen any reason to replace plugs yet. Once we get some consistent misfires and fuel trims, then I would think about swapping the plugs in cylinders 1+2 with 5+6 for further testing. Do not try to check or change the gap on this type of spark plug without training. Very easy to convert a $25 plug to a $2.50 plug. Gap isn't all that critical with style ignition system.