Geroge, my focus is now on post #69 along with a couple of suggestions about fuel flow, most recently by Lou.

In re-reading post #69 you asked, “Would the fuel pressure inline from the pump to the carburetor change when the motor is under a real load on the water compared to running on muffs?” and it did not get fully answered. In fact, when I initially read it, I thought you had put it under load but it seems as if was only a question and did not actually do it.

The answer is yes, it consumes more fuel under load. This is no different when you are towing your boat vs. not towing it, your truck gas milage goes way down when towing.

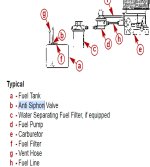

Lou is suggesting that a partial blockage in the fuel delivery, like the anti-siphon valve, could be responsible. So even though you are seeing good pressure on the muffs at all RPMs does not mean will have good pressure under load.

If you still have an opportunity to run the boat on the water my suggestion is now to do so as per post #88. If all is good, then I am back to the restricted exhaust.