I ran this motor a good bit last year. I don't know - maybe 30-50 hours of service. Trolling, just boat rides, etc. Regular use. It seemed to run good, I found a bugger in the carb bowl, and that solve the why is the float sticking question. A piece of the gasket had pinched, and sort of became like a little whisker, that the float was catching on. I pulled it off, put the bowl back on, same gasket, about 10 hours on this motor from fishign this spring.

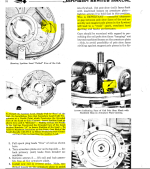

This motor was making a high pitch noise at some RPMs, mid throttle. I pulled the flywheel and it was definitely was rubbing on one of the coils. I couldn't really figure out why, so - just messing around, I took the flyweel off another motor, and it did not seem to contact, or contact as much, so - I did a run test. I cleaned and reset the points while I was in there. I also switched to J6C plugs, I had J4C in it. and ran 93 octane gas, which should make no difference, but it was in the can from testing another motor, where maybe it did matter.

Idles better. Seems like I was able to run it at better trolling speeds and not have it start to caugh and drop a cylinder going too slow. It should be able to do that, it will idle down slow enough you can basically put your finger on the flywheel it is going so slow, but it will only do that for a couple minutes, and then start to slowly drop a cylinder and then stall. But, it woul do this same thing at like a 2.5 mph trolling speed, and RPMs way above an idle. Seemed not to do that today, and it would troll way down fine and run smooth, just guessing, but down to 1.5 mph, slower than I would want to troll for the most part anyway.

It still squealed a bit, but in a much narrower range of the throttle. It is a bad sound, but at least I know what it is. I could go back under the flywheel, but - hey, for now it runs better, squeals less, and should just run good for a long time and I'll live with the little bit of squeal for a second going on and off throttle.

It is a bit loud, but I've heard others of this exact same motor make that same noise over the years, and just never knew what it was. It is a little more noticable coming off throttle, but it definitely rubs going both ways and rings the flyweel.