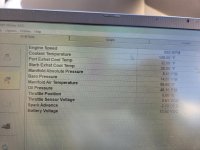

You didn’t post a serial number or even a model number, but I see what looks like an ECM 555 in one of the pictures so I’ll take a guess.

The MerCruiser PWM (pulse width modulatio) IAC is a great source of revenue for shops. I’m not sure why they cause so much trouble in marine applications because it’s the same IAC used trouble free in many Ford automobiles. As near as I can tell they are the second leading cause of ECM failures.

Basically they should rarely run at 0% or near 100%. It seems like you have a problem that needs to be addressed.

If you would like to see what I mean. Use Diacom and run a KOEO test on the IAC. Run it up to 90 or 100% and check the IAC temperature with your finger at 30 seconds and 1 minute. Oh oh, burned your finger? Yes those things run to hot at higher duty cycles. With enough time they will melt the electrical connector and sometimes burn out the wimpy driver circuit in the ECM.

Possible causes?

1. Dirty IAC muffler, these things are (insert rant about parts prices nowadays) cheap. Used to cost about $1.00 but someone recently told me they are $3.00. Still cheap insurance and I recommend they be replaced yearly or more often if your belt is shedding. While you’re at it, clean the flame arreestor because that can cause this issue too.

2. someone messed with the “idle” screw on the throttle body. This is a never touch screw, but I see DIY folks and bad techs do this. The good thing is that MerCruiser usually covers this with a bunch of paint so unless someone replaced the throttle body with the wrong part (this setting can be dependent on model and serial number) you can usually see it.

3. engine is down one or two cylinders. You’d be surprised how often I would hear a V8 missing on one cylinder and the customer has no idea, these modern EFI engines will do a good job of compensating for this problem. Easy test, use the cylinder balance test in Diacom. But if you’re not 100% sure how to run this test—- ask. This is a test that I’ve seen many junior techs do wrong.

4. weak ignition, plugged injectors or other fuel issues and a few more.

Either way, a high IAC duty cycle is a “pay me now or pay me much more later“ issue.