I have had the boat out a couple times after I gave it a quick cleaning and buff job. I straightened a few dings in the prop, got the tach working, got my registration numbers on, got a new hour meter, refinished the swim platform, repaired a cracked blower plenum and basically am now confident that the boat is mechanically sound.

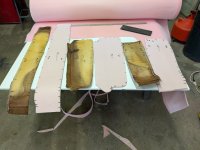

Last week I decided I was done using it for the summer and took the drivers seat to a local upholstery shop I have used before. He found good matches for the vinyl. I told him to order enough vinyl to do the whole interior and start on the somewhat complex drivers seat. He had given me a rough quote of $5K to do the entire upholstery job. That is too much for me to swallow so I told him I may try and learn to do the rest of it myself.

So..... on Friday I am buying a used Consew 206RB-1 industrial sewing machine that is in need of some TLC. I am going to fix up the machine then start practicing sewing with it on scraps. If all goes well, I will get good enough to do the rest of my interior.

Last week I decided I was done using it for the summer and took the drivers seat to a local upholstery shop I have used before. He found good matches for the vinyl. I told him to order enough vinyl to do the whole interior and start on the somewhat complex drivers seat. He had given me a rough quote of $5K to do the entire upholstery job. That is too much for me to swallow so I told him I may try and learn to do the rest of it myself.

So..... on Friday I am buying a used Consew 206RB-1 industrial sewing machine that is in need of some TLC. I am going to fix up the machine then start practicing sewing with it on scraps. If all goes well, I will get good enough to do the rest of my interior.