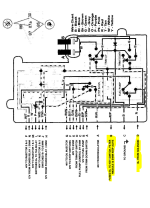

13.2 volts is the voltage you read at the open end of your 2 wires and that is because it is the

HIGHEST point of resistance in the wiring... open air

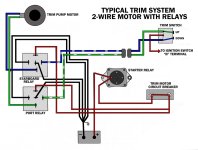

what is missing are amps....stuck somewhere along the wiring is some resistive connection that will allow you to measure that voltage but no amps can properly flow to reach the trim motor.

Could be anything.... between the battery posts and your trim motor.

look for oxydized crimps, rotten wires under the insulation, coroded junction points.

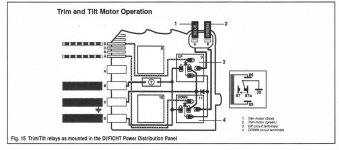

connect up your trim motor try to get it going by pressing up or down switches

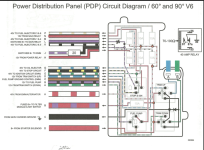

while..... poking tapping twisting the wiring from battery crimp joints, B+ solenenoid connection points, fuse socked , relay sockets etc...

resistive connection genetare heat ...feel around to see if any wires or connections get warm or hot...or start smoking

while holding that trim switch activated

have friend hold the trim switch while you poke around and btw how's the start circuit does the starter spin ok ??.