rjcamel2355

Petty Officer 1st Class

- Joined

- Apr 22, 2015

- Messages

- 221

Hey guys,

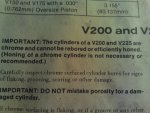

I picked up a 2.4l chrome bore black max last week. Ran a compression on it. 120-125ish on each cylinder EXCEPT #2 being around 80 psi. Squirt a teaspoon of oil it jumped up to 125.

Engine has been setting for 4 or 5 years. It idled fine also ran excellent (prior to and after running the compression)

I'm assuming its a stuck ring, but I figured i would toss it out there and see what everyone else thinks.

Any solutions to bring the compression up?

I've been told I can pull the intake undo the rod bolts pull the head slide the piston out. Quick hone rings and right back in with it.... I've done a few v4 omcs but I had to split the case on those.

I'm not against re ringing one cylinder. But if there's a chance to get the ring to free up I would like to try that.

My grandpa was a gm mechanic and told me stories of using liquid wrench to free it up.

I've personally used atf on cars before and it worked. But I dont want to do that to an outboard unless someone with more knowledge recommends it.

Engine idles great jumps up on a pad and wants to turn a 23p prop way too many rpms it hit 7000 on the tach before I noticed it and I pulled her back down quick (I keep it held back under 5500 usually 4500 just cruising around)

I rebuilt the fuel pump cleaned the carbs new impeller and poppet valve.

Its on a skeeter 150 starfire 17' boat.

I'm not against pulling the head or anything like that but again if its just a stuck ring it seems like a waste of a gasket.

I picked up a 2.4l chrome bore black max last week. Ran a compression on it. 120-125ish on each cylinder EXCEPT #2 being around 80 psi. Squirt a teaspoon of oil it jumped up to 125.

Engine has been setting for 4 or 5 years. It idled fine also ran excellent (prior to and after running the compression)

I'm assuming its a stuck ring, but I figured i would toss it out there and see what everyone else thinks.

Any solutions to bring the compression up?

I've been told I can pull the intake undo the rod bolts pull the head slide the piston out. Quick hone rings and right back in with it.... I've done a few v4 omcs but I had to split the case on those.

I'm not against re ringing one cylinder. But if there's a chance to get the ring to free up I would like to try that.

My grandpa was a gm mechanic and told me stories of using liquid wrench to free it up.

I've personally used atf on cars before and it worked. But I dont want to do that to an outboard unless someone with more knowledge recommends it.

Engine idles great jumps up on a pad and wants to turn a 23p prop way too many rpms it hit 7000 on the tach before I noticed it and I pulled her back down quick (I keep it held back under 5500 usually 4500 just cruising around)

I rebuilt the fuel pump cleaned the carbs new impeller and poppet valve.

Its on a skeeter 150 starfire 17' boat.

I'm not against pulling the head or anything like that but again if its just a stuck ring it seems like a waste of a gasket.