Hi. Working on a 2018 E-Tec 25 hp, model E25DPSLAFD, serial 5526976 .

Runs very poorly when throttled up. Shouldn't leave the dock...

I'd like to at least split the problem between fuel delivery and ignition.

I enhanced the timing marks on the flywheel and added my own for cylinder #2, opposite #1. I put a timing light on and at idle, about 800 rpm, I get a good steady 8 BTDC on #1 and a good steady reading on #2 opposite the 8 mark on the flywheel.

When throttled up all the timing marks disappear and I see nothing through the inspection window. Goes way past the factory 12. The running gets incredibly rough and tries to stall. Doesn't always stall, but its not good. So, when running at lets say fast idle of 2000 or 2500 rpm, what should the timing be? Does it go to 30 or 40 BTDC, outside the viewing window?

Id like to mark the flywheel and verify good or bad ignition at throttle up before I go further.

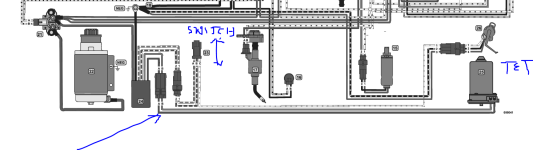

Also, same engine, tilt down does not work. I've verified voltage signal to the motor harness via the helm, so signals and instruction appear to be working. Do the tilt pump motors on E-TEC really just quit.

Losing my confidence in E-TEC...

Thank you,

J

Runs very poorly when throttled up. Shouldn't leave the dock...

I'd like to at least split the problem between fuel delivery and ignition.

I enhanced the timing marks on the flywheel and added my own for cylinder #2, opposite #1. I put a timing light on and at idle, about 800 rpm, I get a good steady 8 BTDC on #1 and a good steady reading on #2 opposite the 8 mark on the flywheel.

When throttled up all the timing marks disappear and I see nothing through the inspection window. Goes way past the factory 12. The running gets incredibly rough and tries to stall. Doesn't always stall, but its not good. So, when running at lets say fast idle of 2000 or 2500 rpm, what should the timing be? Does it go to 30 or 40 BTDC, outside the viewing window?

Id like to mark the flywheel and verify good or bad ignition at throttle up before I go further.

Also, same engine, tilt down does not work. I've verified voltage signal to the motor harness via the helm, so signals and instruction appear to be working. Do the tilt pump motors on E-TEC really just quit.

Losing my confidence in E-TEC...

Thank you,

J