Swift_Striker

Recruit

- Joined

- Jun 26, 2014

- Messages

- 3

Hello Everyone,

I'm quite experienced in automotive engines and decided to take a step into marine engines to fix my father's Regal 1800 LSR with the Penta 4.3 GL.

The Background Information:

We have the boat stored at a marina for the winter and this time, before putting it away, they replaced the impeller claiming it was broken (The temperature gauge never hit the red zone when we were using it, though it ran a little warmer than usual). They ran a test on the engine and have no problems; great. Fast forward to this summer. The marina is getting our boat ready for us and give us some bad news. Supposedly the engine cranked over and would begin to run but it made an unsettling noise which led them to pull the spark plugs. They found water in 2 cylinders and decided to pull the heads. Upon pulling the heads they gave up, they had no ideas what could be wrong as the intake manifold, exhaust manifold, heads, and exhaust manifolds were all uncracked, undamaged, and not warped; According to them at least.

My Goal:

I aim to double check everything the marina checked and more. I think they missed something, or were too hasty to pull everything apart instead of running some diagnostic measures such as a compression test. I know I will soon have to put everything back together and run diagnostics but I don't want to waste gaskets so I'm learning what I can while the top end is apart.

What I've noticed so far:

Cylinder 5 definitely seems to have some sort of issue; the piston is cleaner than the other cylinders and looking at the intake port in the head for this cylinder I can see some foamy glycol (Maybe got in their when the marina took the engine apart or perhaps a crack in the intake/head. I'm not sure what the second cylinder with water in it could be, the rest don't seem to be an issue in terms of a visual inspection.

I spun the crankshaft and checked all the cylinder linings and did not find any cracks.

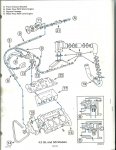

So much for no problems with the intake, found a bunch of rubber junk clogged up in one of the thermostat hose connections as shown in the picture (Does anybody know what this specific fitting's function is? it's on the exhaust side of the thermostat.

Hoping to check out the exhaust manifolds next... Does anybody have any leads I can work on? Any help would be greatly appreciated.

I'm quite experienced in automotive engines and decided to take a step into marine engines to fix my father's Regal 1800 LSR with the Penta 4.3 GL.

The Background Information:

We have the boat stored at a marina for the winter and this time, before putting it away, they replaced the impeller claiming it was broken (The temperature gauge never hit the red zone when we were using it, though it ran a little warmer than usual). They ran a test on the engine and have no problems; great. Fast forward to this summer. The marina is getting our boat ready for us and give us some bad news. Supposedly the engine cranked over and would begin to run but it made an unsettling noise which led them to pull the spark plugs. They found water in 2 cylinders and decided to pull the heads. Upon pulling the heads they gave up, they had no ideas what could be wrong as the intake manifold, exhaust manifold, heads, and exhaust manifolds were all uncracked, undamaged, and not warped; According to them at least.

My Goal:

I aim to double check everything the marina checked and more. I think they missed something, or were too hasty to pull everything apart instead of running some diagnostic measures such as a compression test. I know I will soon have to put everything back together and run diagnostics but I don't want to waste gaskets so I'm learning what I can while the top end is apart.

What I've noticed so far:

Cylinder 5 definitely seems to have some sort of issue; the piston is cleaner than the other cylinders and looking at the intake port in the head for this cylinder I can see some foamy glycol (Maybe got in their when the marina took the engine apart or perhaps a crack in the intake/head. I'm not sure what the second cylinder with water in it could be, the rest don't seem to be an issue in terms of a visual inspection.

I spun the crankshaft and checked all the cylinder linings and did not find any cracks.

So much for no problems with the intake, found a bunch of rubber junk clogged up in one of the thermostat hose connections as shown in the picture (Does anybody know what this specific fitting's function is? it's on the exhaust side of the thermostat.

Hoping to check out the exhaust manifolds next... Does anybody have any leads I can work on? Any help would be greatly appreciated.

Last edited: