Patty85force125

Recruit

- Joined

- Jun 11, 2018

- Messages

- 5

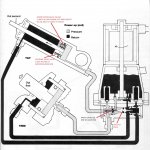

I have a 1985 Force 125, I need more detailed step by step trouble shooting of trim & tilt. I just replaced a Chinese valve body which worked fine but was leaking from threads (all) where lines went in.I replaced this with a API unit at 2.5 times the cost. Now I have severe drift down of motor within minutes. I am not sure if this unit is bad out of the box or if I have other issues. I am following the Clymer manual and at the top of this forum for trouble shooting but need better clarification of which line is which. Can I disconnect all lines and plug to see if I have drift down to see if it is the valve body? Bottom line is I need a diagram of which line is what for all four lines. Also having a a hard time finding brass fittings, have gone to 2 ace stores.. Any help would be appreciated.