TwoRivers

Petty Officer 1st Class

- Joined

- Mar 10, 2010

- Messages

- 344

89 Tracker Tournament V17 Transom

Hello all. Looking for some ideas. I picked up a 1989 Tracker Tournament V17. It needs among other things the wood replaced in the transom. The boat came with a 70hp Johnson TT that I was able to get running. I'm not looking to do a total restore on this boat. It will be a fishing boat and doesn't have to be pretty just safe. The transom needs to be able to hold up to the 70hp plus a 9.9 kicker.

The cap came off pretty easily and the wood looks really bad. Hoping to get enough wood out in one piece to be able to get a pattern for the new wood?

Looking for ideas to remove old wood. I was thinking of driving some really long screws into the more solid areas and trying to lift out?

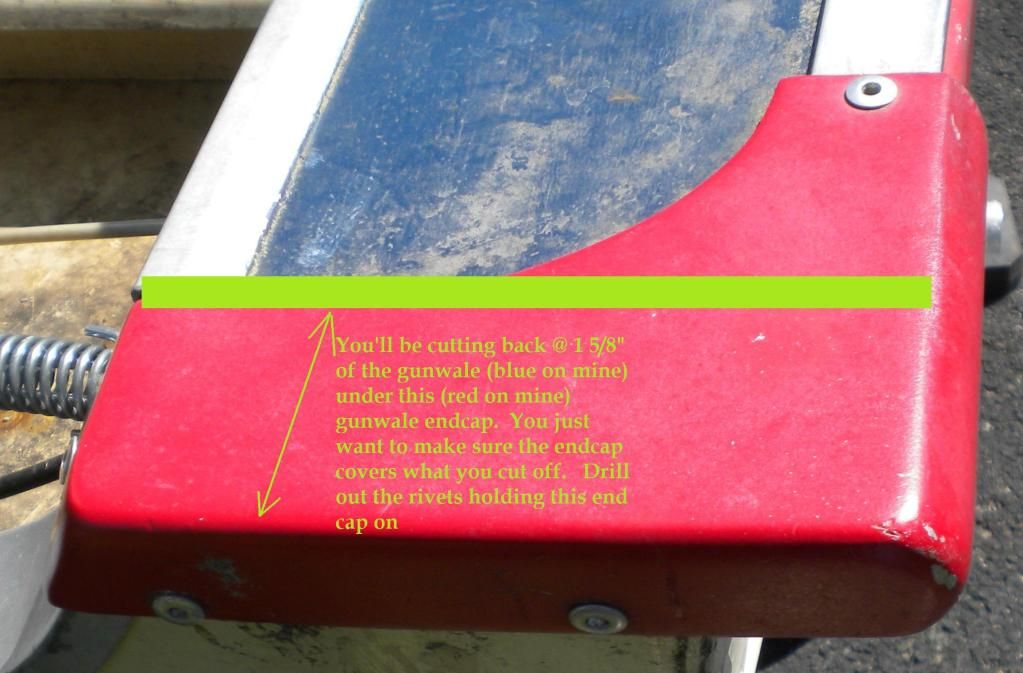

Also the side channels extend over the transom on both side. I think I read on a thread where someone cut the channels to remove the transom wood? Can't remember if they welded them back up or just left them short? Can't find the thread.

Any help appreciated.

thanks

rob

Hello all. Looking for some ideas. I picked up a 1989 Tracker Tournament V17. It needs among other things the wood replaced in the transom. The boat came with a 70hp Johnson TT that I was able to get running. I'm not looking to do a total restore on this boat. It will be a fishing boat and doesn't have to be pretty just safe. The transom needs to be able to hold up to the 70hp plus a 9.9 kicker.

The cap came off pretty easily and the wood looks really bad. Hoping to get enough wood out in one piece to be able to get a pattern for the new wood?

Looking for ideas to remove old wood. I was thinking of driving some really long screws into the more solid areas and trying to lift out?

Also the side channels extend over the transom on both side. I think I read on a thread where someone cut the channels to remove the transom wood? Can't remember if they welded them back up or just left them short? Can't find the thread.

Any help appreciated.

thanks

rob