Grizz1288

Cadet

- Joined

- Jul 31, 2011

- Messages

- 29

I have had an engine 'sneeze' or cough during very low idle (fully warmed up) and have been trying to trouble shoot.

So, I went against everything I have read on the internet and bought a PDF version of the SELOC shop manual for this motor generation. Looking for two things in said manual. 'Link and Sync' procedure and anything about idle tuning.

My idle RPM is dead on at 650 when in the water and in gear and the engine is properly going in and out of 'warming mode'.

The initial needle valves were at 10-1/2 turns out from seated.

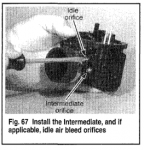

I have attached the portion of the manual that goes over the procedure for tuning the idle needle valves. My questions are:

1) 1st of all as I said this is from SELOC, if anyone has the actual Johnson/Evinrude shop manual and can share its procedure for this I would love to compare them.

2) Does 1/8th of a turn really make enough of an adjustment? I was tuning it yesterday (in the water, fully warm, and in gear), and I could really tell that I was in the right ball park, bc it would either idle just fine or clunk out in a second. I was using full/half turns to fine tune (before I read this) and was getting decent results.

3) This manual procedure makes it seem that each carb is done separately and the valves do not need to be set at the same exact amount of turns. I have read that they should all be set the same (from wisest of internet posters that is). So, what is the verdict, if I turn top left in 1/2-turn do I turn the rest and go from there or can/should each carb be adjusted separately, under the conditions depicted here for the best running engine. What would be the harm in them being set differently?

3.5) Is there a way to tell which cylinder is causing the sneeze?

4) Of all the things that this says must be in order to set the tuning i.e. (in gear, in the water, level trim, fully warm) nothing addresses the fact that the air box and cowling are removed to do these adjustments, uhhh that seems very important in regards to the air flow into the motor. Although I will say, when I got the motor idling fine without any sneeze, putting back on the cowling and air box had no effect.

So, I've gone on and on and anyone reading this post at this point is a true kind soul. Thank you in advance for any insight and help regarding this matter. If you have any further questions that may lead to a more comprehensive response let me know please.

P.S. I didn't mention it above but the carbs were just fully rebuilt and cleaned

So, I went against everything I have read on the internet and bought a PDF version of the SELOC shop manual for this motor generation. Looking for two things in said manual. 'Link and Sync' procedure and anything about idle tuning.

My idle RPM is dead on at 650 when in the water and in gear and the engine is properly going in and out of 'warming mode'.

The initial needle valves were at 10-1/2 turns out from seated.

I have attached the portion of the manual that goes over the procedure for tuning the idle needle valves. My questions are:

1) 1st of all as I said this is from SELOC, if anyone has the actual Johnson/Evinrude shop manual and can share its procedure for this I would love to compare them.

2) Does 1/8th of a turn really make enough of an adjustment? I was tuning it yesterday (in the water, fully warm, and in gear), and I could really tell that I was in the right ball park, bc it would either idle just fine or clunk out in a second. I was using full/half turns to fine tune (before I read this) and was getting decent results.

3) This manual procedure makes it seem that each carb is done separately and the valves do not need to be set at the same exact amount of turns. I have read that they should all be set the same (from wisest of internet posters that is). So, what is the verdict, if I turn top left in 1/2-turn do I turn the rest and go from there or can/should each carb be adjusted separately, under the conditions depicted here for the best running engine. What would be the harm in them being set differently?

3.5) Is there a way to tell which cylinder is causing the sneeze?

4) Of all the things that this says must be in order to set the tuning i.e. (in gear, in the water, level trim, fully warm) nothing addresses the fact that the air box and cowling are removed to do these adjustments, uhhh that seems very important in regards to the air flow into the motor. Although I will say, when I got the motor idling fine without any sneeze, putting back on the cowling and air box had no effect.

So, I've gone on and on and anyone reading this post at this point is a true kind soul. Thank you in advance for any insight and help regarding this matter. If you have any further questions that may lead to a more comprehensive response let me know please.

P.S. I didn't mention it above but the carbs were just fully rebuilt and cleaned