minuteman62-64

Lieutenant

- Joined

- Apr 12, 2011

- Messages

- 1,350

This is kind of a long shot and, yeah, I know it's a dinasour and a limb taker, but I've had it since 1972, it was my first power tool, and I'm kind of attached to it. It's a Craftsman 10-inch Accra-Arm Radial Saw, Model No. 113.29460.

It's done yeoman work for me over the years, but one thing has always bugged me. I can align it perfectly for cross cutting, but it is just a whisker off when I turn the yoke to the in-rip position. I can work with that. However, if I turn the yoke to the out-rip position the blade is measurably off from being 90 degrees to the table. Worse, if I rotate the blade so it is in the position where it is supposed to be parallel to the table, it is way off (maybe 1/8 inch over a 10" blade) from being so.

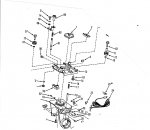

Awhile back I took it apart to do some measuring/diagnosis and determined that there is (I think) a problem with the Carriage Assembly casting (Part #13 on attached drawing). The machined surfaces where the Carriage Bearings (Part #12) are attached are not parallel to the machined bottom part of the Carriage Assembly where it mates with the Yoke Assembly (Part #50).

Now that I'm retired and have some time, out of respect for my old friend, I'd like to fix it. I think I can hand scrape the portion of the bottom of the Carriage Assembly that mates with the Yoke Assembly so it is parallel with the top surfaces. However, I don't want to make things worse through ignorance.

Anybody have any experiance with this model, or a similar problem? Or thoughts? I'd go on one of the metal working sites, but their advice usually starts something like "make a couple of rought passes with your mill ...... ", which I don't have.

Appreciate any input/comments.

It's done yeoman work for me over the years, but one thing has always bugged me. I can align it perfectly for cross cutting, but it is just a whisker off when I turn the yoke to the in-rip position. I can work with that. However, if I turn the yoke to the out-rip position the blade is measurably off from being 90 degrees to the table. Worse, if I rotate the blade so it is in the position where it is supposed to be parallel to the table, it is way off (maybe 1/8 inch over a 10" blade) from being so.

Awhile back I took it apart to do some measuring/diagnosis and determined that there is (I think) a problem with the Carriage Assembly casting (Part #13 on attached drawing). The machined surfaces where the Carriage Bearings (Part #12) are attached are not parallel to the machined bottom part of the Carriage Assembly where it mates with the Yoke Assembly (Part #50).

Now that I'm retired and have some time, out of respect for my old friend, I'd like to fix it. I think I can hand scrape the portion of the bottom of the Carriage Assembly that mates with the Yoke Assembly so it is parallel with the top surfaces. However, I don't want to make things worse through ignorance.

Anybody have any experiance with this model, or a similar problem? Or thoughts? I'd go on one of the metal working sites, but their advice usually starts something like "make a couple of rought passes with your mill ...... ", which I don't have.

Appreciate any input/comments.