CLi87

Petty Officer 1st Class

- Joined

- Sep 21, 2018

- Messages

- 213

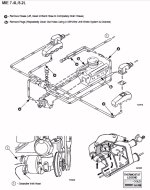

So I finally got my Merc 7.4 up and running and unfortunately after running it for about 20 minutes at idle on the hose I noticed my oil level was rising. I just put new head gaskets and intake manifold gaskets on so I don't think either of those are leaking. I also inspected the heads and block as best I could when I had it apart but didn't see any obvious cracks, although I'm sure there could be a micro crack somewhere that expands as the engine warms up. So before jumping straight to a an internally cracked block, I'd like to rule out everything else it could be. I have a raw water cooled system so it would be quite difficult to test, I would assume disconnect the hose from the oil cooler to the thermostat housing, and then somehow block off the risers? What would be the best way to do this and/or do they sell a block off kit of some kind or do I need to make one?

My main question is if I had a leak somewhere within the exhaust system, could that water get into the crankcase oil? I figure it would leak down into the cylinders but I don't see how water could get into the crankcase? I tried researching this but found quite a few contradicting opinions on this matter. I pulled all the plugs and they all look golden brown and the engine runs fine. I have new manifolds and risers but I re-used the original 3" extension block between them, the side toward the manifolds was smooth but the side toward the risers was a bit pitted, I cleaned it up as best as possible and used plenty of sealant with the gasket, figured it would be fine.

Another possible point of failure I had considered is the oil cooler pipe, what is the proper procedure to test it? And if this was my point of failure, shouldn't I also have water contamination in the power steering fluid?

My main question is if I had a leak somewhere within the exhaust system, could that water get into the crankcase oil? I figure it would leak down into the cylinders but I don't see how water could get into the crankcase? I tried researching this but found quite a few contradicting opinions on this matter. I pulled all the plugs and they all look golden brown and the engine runs fine. I have new manifolds and risers but I re-used the original 3" extension block between them, the side toward the manifolds was smooth but the side toward the risers was a bit pitted, I cleaned it up as best as possible and used plenty of sealant with the gasket, figured it would be fine.

Another possible point of failure I had considered is the oil cooler pipe, what is the proper procedure to test it? And if this was my point of failure, shouldn't I also have water contamination in the power steering fluid?

Last edited: