AndyFromWI

Cadet

- Joined

- Jul 11, 2011

- Messages

- 11

I have worked on multiple mercruiser 2.5 and 3.0 lower units from 1968 to 1979 and this is the first time I have encountered this issue......

History:

The oil in the lower unit was milky, and I had replaced the lower seals a few years ago so I figured it was the upper gear housing assembly seals. I removed the upper assembly, replaced the two oil seals, replaced the seal on the carrier (on the U-Joint yoke).

The problem I'm having is mating the upper and lower half. I have verified that the issue is the pinion gear assembly where it mates on the drive shaft. Basically it rides about 1/4" too high.

If I assemble the top and bottom without the Top Cover Assembly cap, and the carrier gears, it will mate. If I put in the carrier gears (gears attached to the U-Joint yoke), I can put on the Top cover assembly cap, but then I can't mate the upper and lower halves.

I removed the water pump to make sure there was not anything raising the drive shaft up 1/4" and I can freely turn the driveshaft and it will engage the forward and reverse gears.

It seems to me that the pinion gears just do not go far enough down on the driveshaft.

Here are a few pictures explaining the issue.

1/4" gap (Note: water pump and water pipe not installed, gear shift adjust connected properly).

Upper carrier gear installed, top cover installed not torqued, this is how I end up with 1/4" gap between upper and lower cases.

Upper cover removed, note pinion gear bearing is almost flush with top of gearcase.

This looks correct, and the gears mesh properly, but I can't mate the upper and lower case, I have the 1/4" gap.

If I remove the carrier gears, and keep the top cap off, I can mate the upper and lower case, but the top pinion bearing will be raised about 1/4" about the upper case and the carrier gears will not install and the top cover will not install.

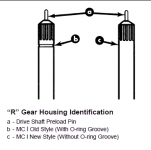

Pinion gear sitting on driveshaft. Does anyone know if it should be sitting 1/4" lower?

The grove in the drive shaft is for the rubber o-ring.

Height of driveshaft with water pump cover and gaskets removed. I'm pretty sure this is the normal height.

I think the problem is that the pinion gear is not going into the driveshaft deeply enough, but I don't want to force it. I have check both the gear and driveshaft mating surfaces for gunk, metal, issues. I have not found anything that stops them from mating.

Can anyone confirm if the pinion gear should be sitting about 1/4" lower on the drive shaft.

I'm stumped. Any help would be appreciated.

-andy

History:

The oil in the lower unit was milky, and I had replaced the lower seals a few years ago so I figured it was the upper gear housing assembly seals. I removed the upper assembly, replaced the two oil seals, replaced the seal on the carrier (on the U-Joint yoke).

The problem I'm having is mating the upper and lower half. I have verified that the issue is the pinion gear assembly where it mates on the drive shaft. Basically it rides about 1/4" too high.

If I assemble the top and bottom without the Top Cover Assembly cap, and the carrier gears, it will mate. If I put in the carrier gears (gears attached to the U-Joint yoke), I can put on the Top cover assembly cap, but then I can't mate the upper and lower halves.

I removed the water pump to make sure there was not anything raising the drive shaft up 1/4" and I can freely turn the driveshaft and it will engage the forward and reverse gears.

It seems to me that the pinion gears just do not go far enough down on the driveshaft.

Here are a few pictures explaining the issue.

1/4" gap (Note: water pump and water pipe not installed, gear shift adjust connected properly).

Upper carrier gear installed, top cover installed not torqued, this is how I end up with 1/4" gap between upper and lower cases.

Upper cover removed, note pinion gear bearing is almost flush with top of gearcase.

This looks correct, and the gears mesh properly, but I can't mate the upper and lower case, I have the 1/4" gap.

If I remove the carrier gears, and keep the top cap off, I can mate the upper and lower case, but the top pinion bearing will be raised about 1/4" about the upper case and the carrier gears will not install and the top cover will not install.

Pinion gear sitting on driveshaft. Does anyone know if it should be sitting 1/4" lower?

The grove in the drive shaft is for the rubber o-ring.

Height of driveshaft with water pump cover and gaskets removed. I'm pretty sure this is the normal height.

I think the problem is that the pinion gear is not going into the driveshaft deeply enough, but I don't want to force it. I have check both the gear and driveshaft mating surfaces for gunk, metal, issues. I have not found anything that stops them from mating.

Can anyone confirm if the pinion gear should be sitting about 1/4" lower on the drive shaft.

I'm stumped. Any help would be appreciated.

-andy