San_Diego_SeaRay

Petty Officer 1st Class

- Joined

- Nov 9, 2014

- Messages

- 343

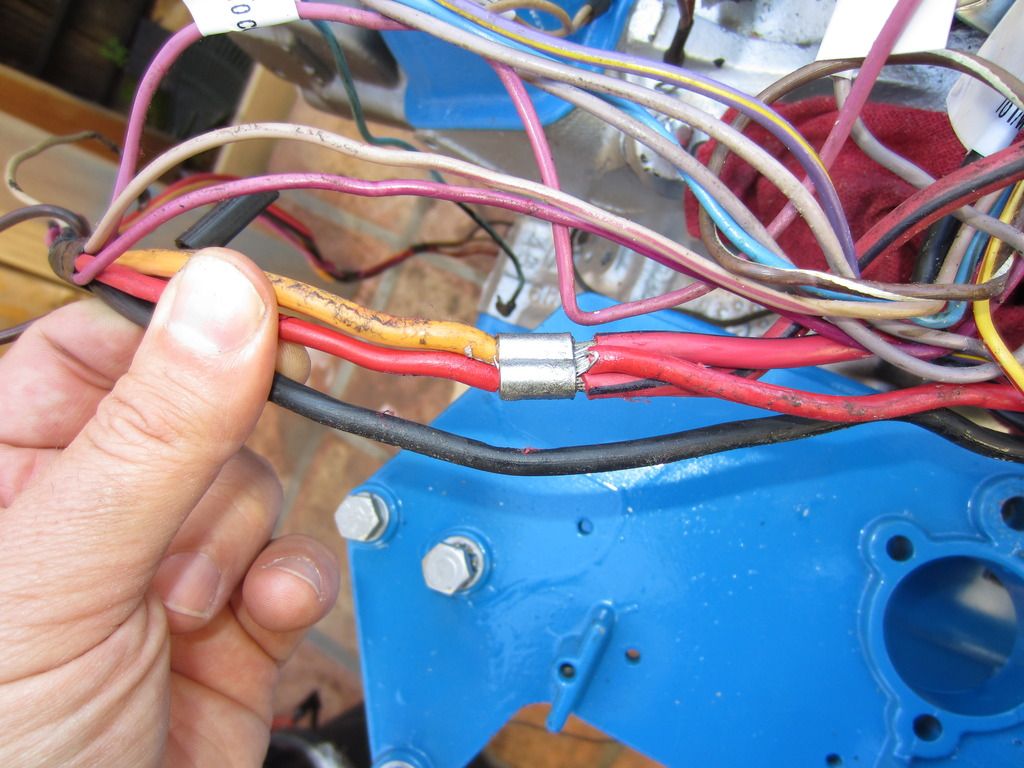

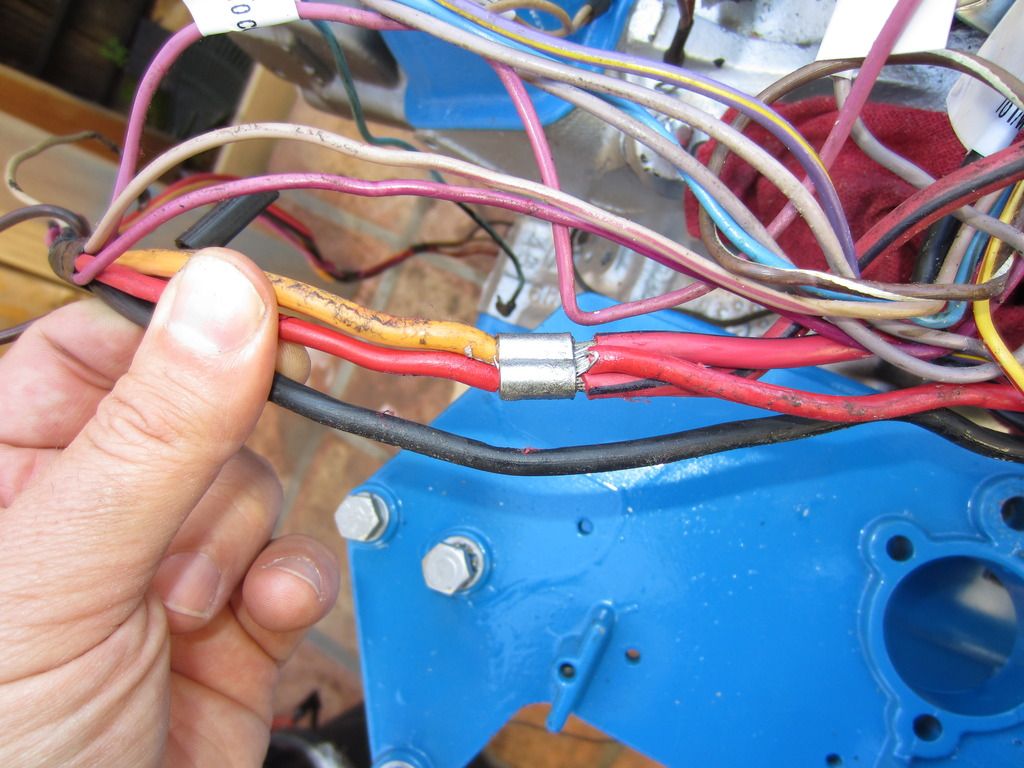

Decided to replace the harness wiring on my 1981 Mercruiser MCM260 engine. I'll keep the harness plug and splice all the new wires into it, but everything else is getting new wire. I've come across a problem though. You can see from the picture how Mercruiser has created an inline "junction" by crimping a ferrous band around four wires (Picture 1). Problem is I don't know where to get these bands; maybe they don't make them anymore. So I went to Home Depot and found an aluminum ferrule set like the one pictured (Picture 2). But apparently copper and aluminum don't play well together and these shouldn't be used for crimping copper wire together. *If* these ferrules were steel, they'd be perfect. So two questions:

- Where do you think I can source steel ferrules locally? What kind of store would carry them?

- Is there a different, better, more modern method of creating this junction? Keep in mind this is in a harness and things like distribution blocks, etc. would not work well.