I recently rebuilt the lower unit, magneto, and carb on a non-working 1957 7.5hp. After reassembling lower unit the driveshaft turned but hard. Other (smarter) members advised this shouldn't be the case so I pulled it apart again, visually checked everything seem to align and mesh properly, but same thing once assembled again. I saw surface rust on the lower shaft and figured (naively) maybe it was just tight from sitting dry for so many years and needed to be run to lube/loosen up the interface between parts, seals, etc.

Sure thing it fired up- had a little rattle from the recoil spring but I didn't sense a strain on the motor. Had a few good outings and maybe 5th time out felt like I could hear a rub, felt like motor was struggling against throttle. Stop being paranoid, I told myself. A minute later wham - it threw hard to the side, and seized. Confirmed this week that the lower shaft sheared inside of that wider collar. Other gears/splines look undamaged, but a couple things strike out at me:

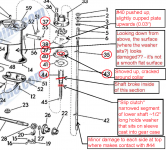

1) My lower shaft doesn't match the schematic. Mine has a narrowed segment that would sit above the sleeve in the gear case, with a washer (see photo). Is this normal, so the shaft doesn't spin directly on the aluminum gear case?

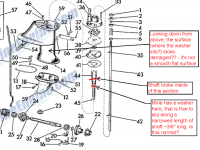

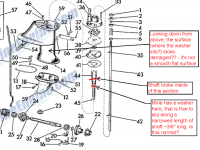

2) Where that washer would sit (looking down the gear case from above) the surface is pitted/damaged. Almost looks like two tabs on one side, or like the aluminum wall is torn up. But I didn't find any metal fragments.

Kinda unsure on next steps. I'd rather not install a used replacement shaft just to repeat the process. Except for the surface where the lower shaft/washer sits, the gear case looks good but I don't know if it's salvagable. And from what I hear the quality of used cases are hit or miss.

??

Looking down into gear case housing:

Sure thing it fired up- had a little rattle from the recoil spring but I didn't sense a strain on the motor. Had a few good outings and maybe 5th time out felt like I could hear a rub, felt like motor was struggling against throttle. Stop being paranoid, I told myself. A minute later wham - it threw hard to the side, and seized. Confirmed this week that the lower shaft sheared inside of that wider collar. Other gears/splines look undamaged, but a couple things strike out at me:

1) My lower shaft doesn't match the schematic. Mine has a narrowed segment that would sit above the sleeve in the gear case, with a washer (see photo). Is this normal, so the shaft doesn't spin directly on the aluminum gear case?

2) Where that washer would sit (looking down the gear case from above) the surface is pitted/damaged. Almost looks like two tabs on one side, or like the aluminum wall is torn up. But I didn't find any metal fragments.

Kinda unsure on next steps. I'd rather not install a used replacement shaft just to repeat the process. Except for the surface where the lower shaft/washer sits, the gear case looks good but I don't know if it's salvagable. And from what I hear the quality of used cases are hit or miss.

??

Looking down into gear case housing: