So I've tried changing my water pump impeller with a kit for my Alpha 1 Gen II. First off, when I've separated the upper from the lower unit, these two metal parts came off. I've looked multiple times in the service manual, but I can't seem to figure out where from. Anyone know?

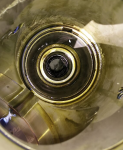

And one more question - my kit didn't have the seal for the drive shaft (http://www.iboats.com/Face-Seal-Tool-18-2599-Sierra/dm/view_id.172013) and it didn't come off from the upper unit when I've separated them. So I've started prying the upper unit seal thinking it got stuck there. But then I've noticed that underneath it had some metallic spring "seal" (hope the pictures below are clear enough to get an idea what I'm talking about).

Is this some other seal? I've broken a part of it trying to get it out, do I need to replace it now and how?

I don't see any metallic spring in these diagrams (http://www.iboats.com/Mercruiser-Gen-II-Lower-Gearcase-Assembly-Exploded-View/dm/view_id.272971) so I'm quite confused now :|

And one more question - my kit didn't have the seal for the drive shaft (http://www.iboats.com/Face-Seal-Tool-18-2599-Sierra/dm/view_id.172013) and it didn't come off from the upper unit when I've separated them. So I've started prying the upper unit seal thinking it got stuck there. But then I've noticed that underneath it had some metallic spring "seal" (hope the pictures below are clear enough to get an idea what I'm talking about).

Is this some other seal? I've broken a part of it trying to get it out, do I need to replace it now and how?

I don't see any metallic spring in these diagrams (http://www.iboats.com/Mercruiser-Gen-II-Lower-Gearcase-Assembly-Exploded-View/dm/view_id.272971) so I'm quite confused now :|