blubber2023

Cadet

- Joined

- May 11, 2023

- Messages

- 7

Hello,

I have 1979 Johnson 9.9HP. I installed new water pump, impeller, fuel pump, fuel lines, spark plugs. Carburetor cleaned with repair kit. All seems working fine.

I have single handle throttle. I can not start the engine in neutral. If I push throttle arm, it goes in shift and if i push further, i can start the engine. That means i can start my engine in shift but not in neutral.

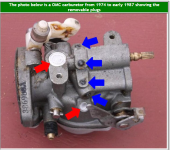

I removed the air intake box to have access to the throttle linkage and roller.

If i gently push the roller/throttle linkage with my finger, I can start the engine and it runs in neutral with that gentle push on the roller/throttle linkage. If I remove my finger, engine stops.

It feels like initial position of throttle linkage is not correct. How can I adjust that?

The small screw on the plastic part does not help although its all tightened up.

Notes:

In neutral, throttle cam does not touch roller.

Any ideas?

thank you,

Erhan

I have 1979 Johnson 9.9HP. I installed new water pump, impeller, fuel pump, fuel lines, spark plugs. Carburetor cleaned with repair kit. All seems working fine.

I have single handle throttle. I can not start the engine in neutral. If I push throttle arm, it goes in shift and if i push further, i can start the engine. That means i can start my engine in shift but not in neutral.

I removed the air intake box to have access to the throttle linkage and roller.

If i gently push the roller/throttle linkage with my finger, I can start the engine and it runs in neutral with that gentle push on the roller/throttle linkage. If I remove my finger, engine stops.

It feels like initial position of throttle linkage is not correct. How can I adjust that?

The small screw on the plastic part does not help although its all tightened up.

Notes:

In neutral, throttle cam does not touch roller.

Any ideas?

thank you,

Erhan

Last edited: