89 Merc 3.7

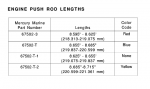

So after redoing my top end place in the head gasket I finally got the boat running nicely. After about an hour and a half I noticed a ticking noise a little sputtering and then the engine died. On a hunch when I got home after seeing it run really rough I said let me take the valve cover off and sure enough to the pushrods we’re out now I torque these things according to specifications 20 pounds which to me is awful light. I wanted to do at least40 but the manual cars for 20 so I’m confused because 20 is not very tight am I allowed to just tighten these as much as I can without stripping the bolt let’s say 60 pounds.

So after redoing my top end place in the head gasket I finally got the boat running nicely. After about an hour and a half I noticed a ticking noise a little sputtering and then the engine died. On a hunch when I got home after seeing it run really rough I said let me take the valve cover off and sure enough to the pushrods we’re out now I torque these things according to specifications 20 pounds which to me is awful light. I wanted to do at least40 but the manual cars for 20 so I’m confused because 20 is not very tight am I allowed to just tighten these as much as I can without stripping the bolt let’s say 60 pounds.

Attachments

Last edited: