Sea Rider

Supreme Mariner

- Joined

- Sep 20, 2008

- Messages

- 12,345

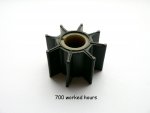

My current 18 horse which is our guinea pig for experimentation, just had it’s 5th Happy Birthday and was literally virgin regarding mayor general gasket maintenance, with 700 metered constant worked hours wanting to see if well treated and cared for would surrender any advantage.

First issue noticed after removing engine from base, base gasket completey dried out and burned at the exhaust port portion, some E, 2 strokes oil & salt water crude, jamming water holes, specially small internal peeing hole which is thin in diameter.

Cylinder head was literally solded, bolts were removed with extreme patience with socket wrench and extension so not to break bolts or damage threads. The head gasket was extremely hardened & dried out, overall crankcase and head internal salf formation was found very low, just 10%. In part due that with engine on, is flushed with good water pressure for 10 minutes after it’s use.

Pistons and cylinder head had only 3% carbon deposits, after squirting some Power Tuner on them, letting soak for 10 minutes, thin deposit was completely removed with a tooth brush, looks like new. Both cylinder walls in excellent smooth & polished condition due to use of high octane gasoline and good 2 stroke oil with correct gas/oil mixture.

Although some states that using high grade octane gasolines is a waste of money, find that by having better cleanning aditives will burn much efficiently leaving less carbon build up on pistons and head as have been able to corroborate on this occasion. Find that using higher octane gasolines the engine has more punch consumming less fuel while throttling less compared to less octane gasolines.

Took advantage to clean thermostat housing, all water paths and exhaust system which is always a mess to clean on any 2 strokes engine. With saintly patience removed old gaskets and lightly sanded metal surfaces to receive new replacement gaskets.

On previous engines owned used to perform a complete gasket maintenance every 300 hours, as our engines are used all year round, that should be around every 2 years. If you see small salt formation side to gaskets, it’s gasket change time, better change to avoid corrotion on spotted leak. If it’s a head gasket small leak and you like to go extreme wot boating, be aware of blown head gasket...

Fuel systems, tank, hose, bulb, fuel pump, filter & carb are inmaculate clean, after finishing with crankcase gasket aseembly and torque to specs, will have a look at water pump, we like to polish liner and guide plate every 200 worked hours this assures long impeller life and smooth operation inside liner. All moving and sliding parts have been greased including magneto base, now throttle turns as butter.

Excellent time to change carb gasket, the one that seats and seals carb throat to manifold, old ones could let air in and at wot have bad top performance issues.

Bottomline : prevent rather than regret...

Happy Boating

First issue noticed after removing engine from base, base gasket completey dried out and burned at the exhaust port portion, some E, 2 strokes oil & salt water crude, jamming water holes, specially small internal peeing hole which is thin in diameter.

Cylinder head was literally solded, bolts were removed with extreme patience with socket wrench and extension so not to break bolts or damage threads. The head gasket was extremely hardened & dried out, overall crankcase and head internal salf formation was found very low, just 10%. In part due that with engine on, is flushed with good water pressure for 10 minutes after it’s use.

Pistons and cylinder head had only 3% carbon deposits, after squirting some Power Tuner on them, letting soak for 10 minutes, thin deposit was completely removed with a tooth brush, looks like new. Both cylinder walls in excellent smooth & polished condition due to use of high octane gasoline and good 2 stroke oil with correct gas/oil mixture.

Although some states that using high grade octane gasolines is a waste of money, find that by having better cleanning aditives will burn much efficiently leaving less carbon build up on pistons and head as have been able to corroborate on this occasion. Find that using higher octane gasolines the engine has more punch consumming less fuel while throttling less compared to less octane gasolines.

Took advantage to clean thermostat housing, all water paths and exhaust system which is always a mess to clean on any 2 strokes engine. With saintly patience removed old gaskets and lightly sanded metal surfaces to receive new replacement gaskets.

On previous engines owned used to perform a complete gasket maintenance every 300 hours, as our engines are used all year round, that should be around every 2 years. If you see small salt formation side to gaskets, it’s gasket change time, better change to avoid corrotion on spotted leak. If it’s a head gasket small leak and you like to go extreme wot boating, be aware of blown head gasket...

Fuel systems, tank, hose, bulb, fuel pump, filter & carb are inmaculate clean, after finishing with crankcase gasket aseembly and torque to specs, will have a look at water pump, we like to polish liner and guide plate every 200 worked hours this assures long impeller life and smooth operation inside liner. All moving and sliding parts have been greased including magneto base, now throttle turns as butter.

Excellent time to change carb gasket, the one that seats and seals carb throat to manifold, old ones could let air in and at wot have bad top performance issues.

Bottomline : prevent rather than regret...

Happy Boating