I had a rusted out stove pipe to heat-type choke actuator so decided to convert to electric choke, which works great, however there is a linkage arm that runs from the choke shaft down and connects to the fast idle cam that functions as an idle screw stop. At idle, the screw rests against the stop, but this makes it so the choke shaft above cannot rotate. This is okay, as long as the choke is in the position you want it when you are ready to idle. This doesn't seem right to me, for example if you turn off the engine at idle (warm engine choke fully open), the cam stop will not allow the linkage to rotate the choke shaft closed for the next cold start. Wonder if I am missing something, or perhaps that linkage arm should be removed when converting from hot air to electric choke.

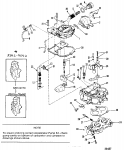

In the attached photo, the linkage is #7, cam is #22, stop screw is #26.

In the attached photo, the linkage is #7, cam is #22, stop screw is #26.