Lostuzer

Cadet

- Joined

- Jul 5, 2007

- Messages

- 25

Hello,

If this topic has been discussed before I plead with you for directions to the place. Unfortunately I couldn't find any information concerning my problem.

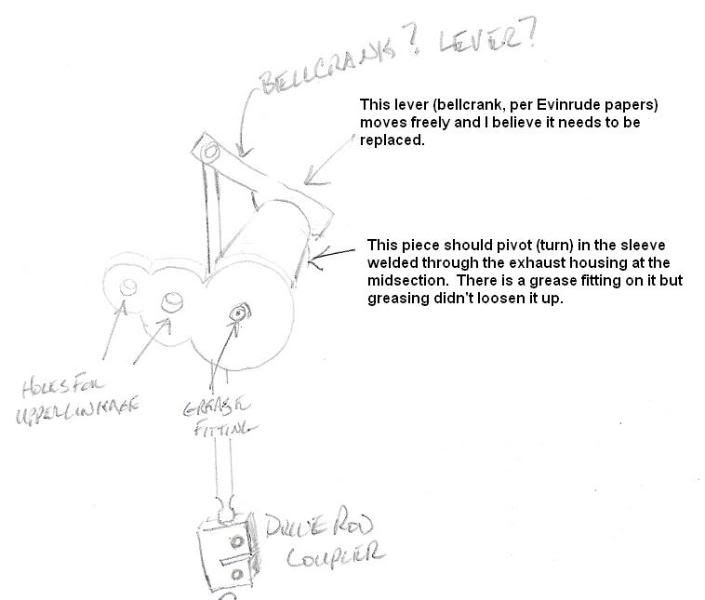

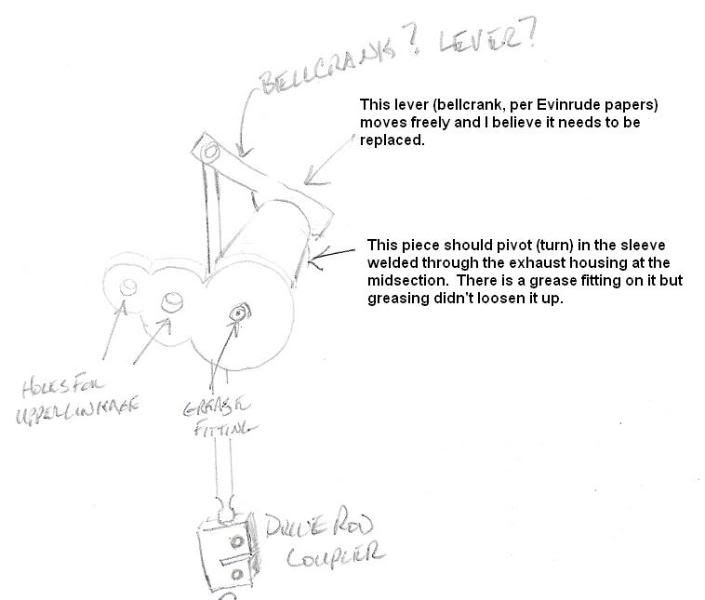

I bought an Evinrude 1961 75HP Starflite III Mod. 50525 SN. 04272 and have been going through it to assertain what I have. So far everything "looks" favorable (lower unit, compression, ext.) except for a problem with shifting. Little is said in my service manual; actually all mention of this area I have uploaded for you to see.

My question is: To replace the Lever/(Bellcrank) and the shiftrod will I have to pull the power head and if so where can I get good instruction?

Thanks,

Bob

If this topic has been discussed before I plead with you for directions to the place. Unfortunately I couldn't find any information concerning my problem.

I bought an Evinrude 1961 75HP Starflite III Mod. 50525 SN. 04272 and have been going through it to assertain what I have. So far everything "looks" favorable (lower unit, compression, ext.) except for a problem with shifting. Little is said in my service manual; actually all mention of this area I have uploaded for you to see.

My question is: To replace the Lever/(Bellcrank) and the shiftrod will I have to pull the power head and if so where can I get good instruction?

Thanks,

Bob