Hi all,

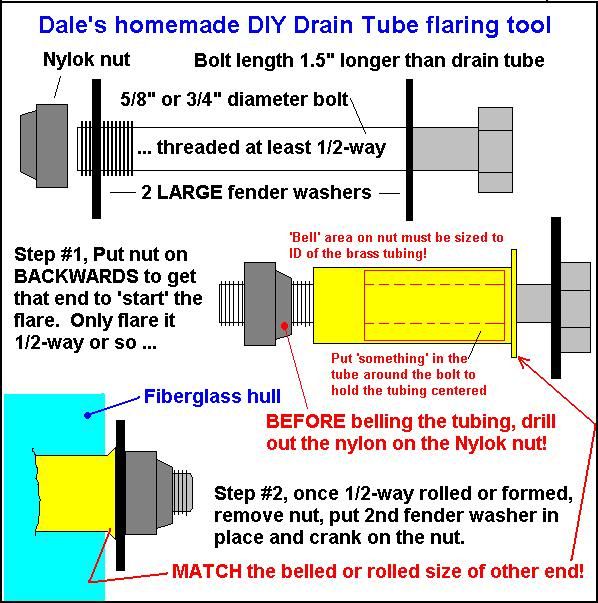

I posted earlier about my project, which is going well. Just a question. This is a 64 model. There are drain holes through the transom for the splash well and the bilge. They appear to be light gauge brass tubes, beaded on one end, that were inserted through a hole in the transom and flared to make a seal. So I guess there are two questions: Am I right about the method, and how do I get them out? I am assuming the I either bang them or drill them out. Knowing what it means to assume, I decided to inquire here first. Any help will be appreciated.

Jules

I posted earlier about my project, which is going well. Just a question. This is a 64 model. There are drain holes through the transom for the splash well and the bilge. They appear to be light gauge brass tubes, beaded on one end, that were inserted through a hole in the transom and flared to make a seal. So I guess there are two questions: Am I right about the method, and how do I get them out? I am assuming the I either bang them or drill them out. Knowing what it means to assume, I decided to inquire here first. Any help will be appreciated.

Jules