I have used

NOROX®

MCP-75, ( chemical name Methyl ethyl ketone peroxide/Cumyl hydroperoxide), which is Red vs. the regular clear MEKP.

Not sure if that is what you are referring to . . .

The MCP is a slower catalyst, so yes working time is increased. I have also used "TBC" inhibitor (4-tert-Butylcatechol

) with the regular MEKP, which also extends working time, but in a different way.

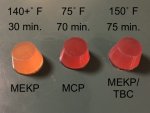

Here is a picture of some test samples I made of the various catalyst combinations I used in a recent project, showing time to first 'gel' and peak curing temperature. These are with Vinyl Ester (VE) resin. I think all of the starting temperatures were around 55˚ F, so fairly cold for resin

.

.

I think the extra chemical in the Red Norox (Cumyl hydroperoxide) acts as an inhibitor to the MEKP, much like the TBC. The big difference that you can see is, once the TBC effects is over, the MEKP really kicks into gear and produces a lot of heat vs. the MCP. More heat can be good in cases where you need the resin to generate a fair amount of heat, but too much heat may cause irregularities in the surface of the part if your are making a part from a mold.