Lostuzer

Cadet

- Joined

- Jul 5, 2007

- Messages

- 25

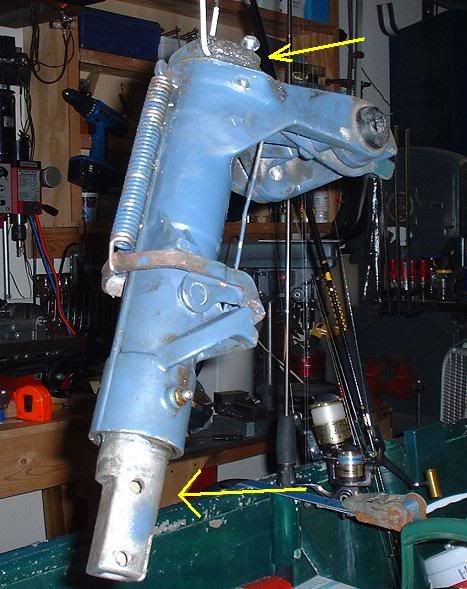

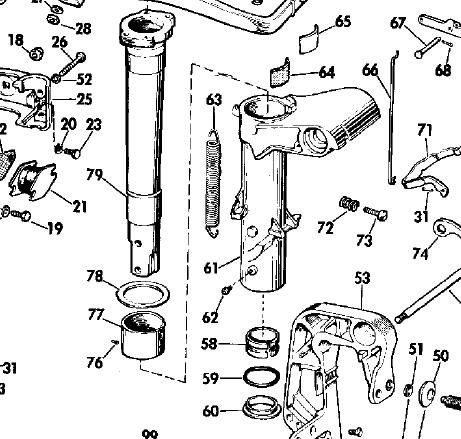

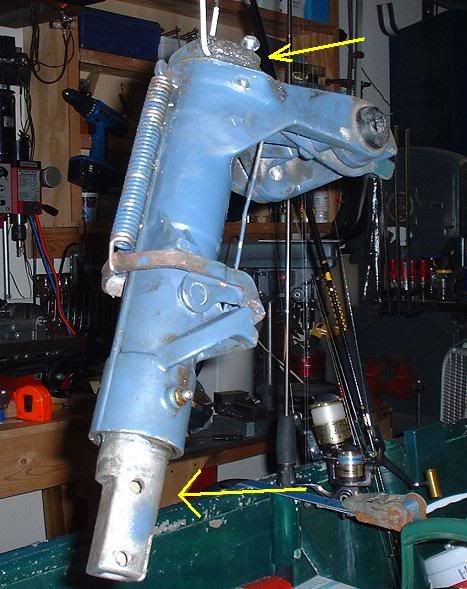

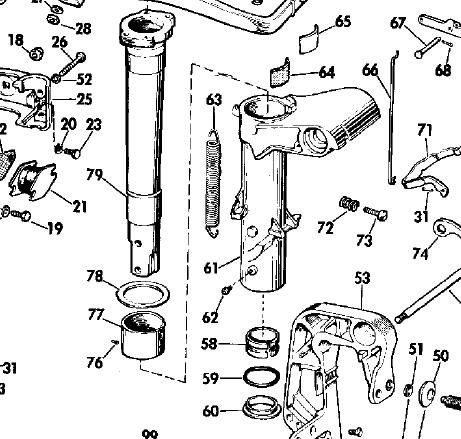

18902D ? E12329 ?1969? 18hp Evinrude Fastwin

(Converted to short shaft)

I broke my drive shaft the other day and decided while I was down and partially apart to clean, paint, lube, replace belly pan mount, etc, until I could find a replacement drive shaft I can afford (26 X ? 4 spline and 11 spline).

I?ve always had a problem with the steering being a little too tight for my taste so I thought I might as well tear that part down and clean and re-lube with fresh marine grease.

I removed the thrust washer (plastic ring) and ?O? ring from the bottom of the assembly and the Co-pilot adjustment screw and spring from the upper area.

I at first tried to tap the shaft out with a 24oz. ball peen and a piece of aluminum bar stock as a buffer but as I proceeded the assembly became much tighter. At about an inch of headway I was cringing at the amount of force I had to use.

I then reversed directions using a wooden 2X4 as a buffer. Now, back in it?s normal position, it is no looser or tighter than before.

I then applied heat with a propane torch and tried pulling as I twisted back and forth (no hammer blows this time}. It moved up about an eighth of an inch AND got much tighter as it was displaced.

Could anyone give me the SOP for removing this?

Thanks,

Bob

(Converted to short shaft)

I broke my drive shaft the other day and decided while I was down and partially apart to clean, paint, lube, replace belly pan mount, etc, until I could find a replacement drive shaft I can afford (26 X ? 4 spline and 11 spline).

I?ve always had a problem with the steering being a little too tight for my taste so I thought I might as well tear that part down and clean and re-lube with fresh marine grease.

I removed the thrust washer (plastic ring) and ?O? ring from the bottom of the assembly and the Co-pilot adjustment screw and spring from the upper area.

I at first tried to tap the shaft out with a 24oz. ball peen and a piece of aluminum bar stock as a buffer but as I proceeded the assembly became much tighter. At about an inch of headway I was cringing at the amount of force I had to use.

I then reversed directions using a wooden 2X4 as a buffer. Now, back in it?s normal position, it is no looser or tighter than before.

I then applied heat with a propane torch and tried pulling as I twisted back and forth (no hammer blows this time}. It moved up about an eighth of an inch AND got much tighter as it was displaced.

Could anyone give me the SOP for removing this?

Thanks,

Bob