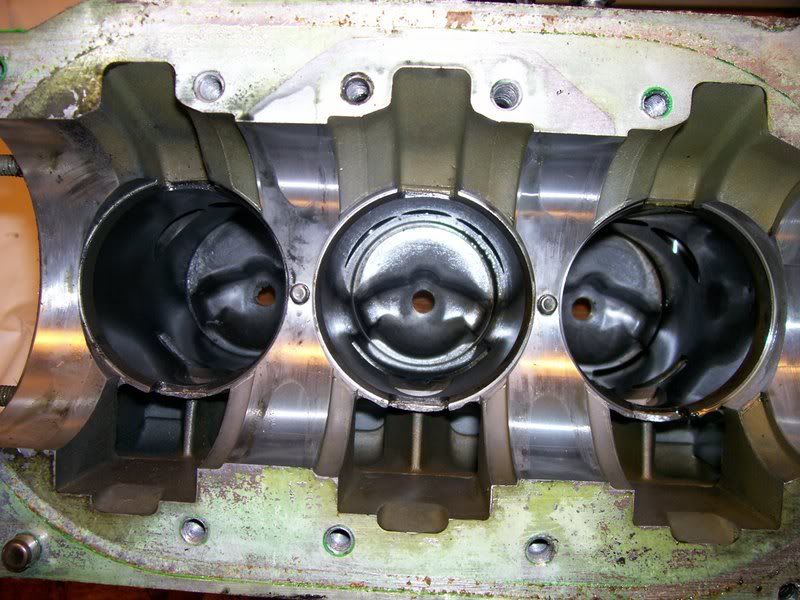

Hi all. I am rebuilding a 1985 Merc 60HP 3 Cyl.

so far I have been positively surprised that nothing is mangled beyond repair inside, as I bought the engine with a toasted cylinder 1, and it had run for quite some time with that, according to the seller.

Well, my question is: The cylinders look fine, I even think it will run std. after a clean-up, but the head has a problem that I am not sure what to do about.

It would seem that some sort of pitting happened in the far corner of cyl 1?s combustion chamber. weather if it where there before the piston went up in smoke, I don't know, but I am a little concerned that it will cause a hot spot, and fry my new piston if left untouched. Should I grind it down and risk disturbing combustion, or should I just ignore it?

As to what caused the problem i don't know, but my prelim theory is failure to retard ignition during load. The wiring harness is banged up.

Can anybody give some opinions on this piston damage?

last question: The pistons read: 744-9188 for parts number, I just cant find it in my EPC, does anybody know what these pistons are? Std. 0.15 etc.?

Best regards

Rasmus

Edited due to obscene language

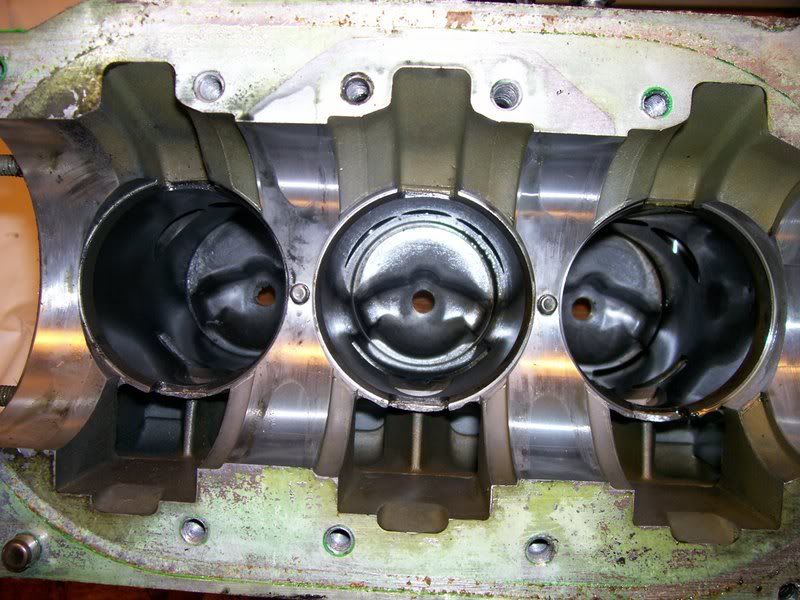

so far I have been positively surprised that nothing is mangled beyond repair inside, as I bought the engine with a toasted cylinder 1, and it had run for quite some time with that, according to the seller.

Well, my question is: The cylinders look fine, I even think it will run std. after a clean-up, but the head has a problem that I am not sure what to do about.

It would seem that some sort of pitting happened in the far corner of cyl 1?s combustion chamber. weather if it where there before the piston went up in smoke, I don't know, but I am a little concerned that it will cause a hot spot, and fry my new piston if left untouched. Should I grind it down and risk disturbing combustion, or should I just ignore it?

As to what caused the problem i don't know, but my prelim theory is failure to retard ignition during load. The wiring harness is banged up.

Can anybody give some opinions on this piston damage?

last question: The pistons read: 744-9188 for parts number, I just cant find it in my EPC, does anybody know what these pistons are? Std. 0.15 etc.?

Best regards

Rasmus

Edited due to obscene language