minuteman62-64

Lieutenant

- Joined

- Apr 12, 2011

- Messages

- 1,350

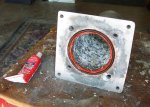

My spa has an old style (1980's) cast aluminum heater housing. The grove for the "O" ring that seals against the electric heater element is badly corroded - particularly the ridge that forms the inside circumfrence). See attached photo.

Last time (maybe 10 years ago) I repaired a small area with JB Weld. This time the damage is quite a bit more extensive, and I'm thinking another approach.

I'm thinking of putting a bed of high-temp silicone in the "O" ring groove and bedding a new "O" ring in the silicone and letting it set up. Then assemble, hoping the set-up silicone has filled the gaps and will maintain a seal.

I need to get 6 months to 2 years out of this repair before I either rebuild the spa or get a new one.

What do you think? Will it work?

Last time (maybe 10 years ago) I repaired a small area with JB Weld. This time the damage is quite a bit more extensive, and I'm thinking another approach.

I'm thinking of putting a bed of high-temp silicone in the "O" ring groove and bedding a new "O" ring in the silicone and letting it set up. Then assemble, hoping the set-up silicone has filled the gaps and will maintain a seal.

I need to get 6 months to 2 years out of this repair before I either rebuild the spa or get a new one.

What do you think? Will it work?