New to posting.

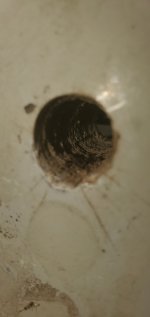

So just got this boat(1984 Bomber Scout) this year and took it on Mississippi River and handled it surprisingly fine and found a leak by the time we got back and surprisingly didn't sink, the transom must've been really weak and rotted when I got it but the boat still looked great. The motor that came on it is 77' 75hp evinrude and that's over the data plate by 5hp I believe if the data plate wasn't scratched over to 70hp... online shows both 60hp and 70hp max for my boat depending on source. But now I'm wondering best way to fix this. I've got some experience with woodworking working in lumber yard and my brother has experience with fiberglass work on aircrafts but none of us are well experience on boats that much. I've watch many videos of people cutting from back and such. I haven't asked locally around really if anyone does transom or boat repair in my area, I live in missouri and not sure if I want to bother bc it would cost more than the boats worth most likely and i dont want to spend insane amount. Already got engine off and thinking about splitting the hull top to bottom between the seal if possible. Please let me know what would be my best options or advice!

So just got this boat(1984 Bomber Scout) this year and took it on Mississippi River and handled it surprisingly fine and found a leak by the time we got back and surprisingly didn't sink, the transom must've been really weak and rotted when I got it but the boat still looked great. The motor that came on it is 77' 75hp evinrude and that's over the data plate by 5hp I believe if the data plate wasn't scratched over to 70hp... online shows both 60hp and 70hp max for my boat depending on source. But now I'm wondering best way to fix this. I've got some experience with woodworking working in lumber yard and my brother has experience with fiberglass work on aircrafts but none of us are well experience on boats that much. I've watch many videos of people cutting from back and such. I haven't asked locally around really if anyone does transom or boat repair in my area, I live in missouri and not sure if I want to bother bc it would cost more than the boats worth most likely and i dont want to spend insane amount. Already got engine off and thinking about splitting the hull top to bottom between the seal if possible. Please let me know what would be my best options or advice!

Attachments

-

20220522_162838.jpg2.6 MB · Views: 10

20220522_162838.jpg2.6 MB · Views: 10 -

20220514_121328.jpg3.8 MB · Views: 12

20220514_121328.jpg3.8 MB · Views: 12 -

20220815_140759.jpg2.9 MB · Views: 13

20220815_140759.jpg2.9 MB · Views: 13 -

20220815_140817.jpg3.2 MB · Views: 13

20220815_140817.jpg3.2 MB · Views: 13 -

20220815_142623.jpg3.2 MB · Views: 13

20220815_142623.jpg3.2 MB · Views: 13 -

20220815_140827.jpg3.7 MB · Views: 12

20220815_140827.jpg3.7 MB · Views: 12 -

20220815_141012.jpg4.4 MB · Views: 12

20220815_141012.jpg4.4 MB · Views: 12 -

20220815_141024.jpg1.2 MB · Views: 11

20220815_141024.jpg1.2 MB · Views: 11 -

20220815_141112.jpg3.7 MB · Views: 10

20220815_141112.jpg3.7 MB · Views: 10 -

20220815_141118.jpg3.5 MB · Views: 10

20220815_141118.jpg3.5 MB · Views: 10 -

20220815_141134.jpg1.5 MB · Views: 10

20220815_141134.jpg1.5 MB · Views: 10 -

20220815_141142.jpg4 MB · Views: 9

20220815_141142.jpg4 MB · Views: 9 -

20220815_141146.jpg4.2 MB · Views: 9

20220815_141146.jpg4.2 MB · Views: 9 -

20220815_141240.jpg672.2 KB · Views: 9

20220815_141240.jpg672.2 KB · Views: 9 -

20220815_141258.jpg716.1 KB · Views: 9

20220815_141258.jpg716.1 KB · Views: 9 -

20220815_141300.jpg734 KB · Views: 8

20220815_141300.jpg734 KB · Views: 8 -

20220815_141325.jpg1.3 MB · Views: 8

20220815_141325.jpg1.3 MB · Views: 8 -

20220815_141332.jpg1 MB · Views: 8

20220815_141332.jpg1 MB · Views: 8 -

20220815_141338.jpg899.1 KB · Views: 8

20220815_141338.jpg899.1 KB · Views: 8 -

20220815_141341.jpg1.1 MB · Views: 8

20220815_141341.jpg1.1 MB · Views: 8 -

20220815_141347.jpg1,007.6 KB · Views: 9

20220815_141347.jpg1,007.6 KB · Views: 9 -

20220815_142632.jpg6 MB · Views: 10

20220815_142632.jpg6 MB · Views: 10