MassillonBuckeye

Chief Petty Officer

- Joined

- Jul 26, 2010

- Messages

- 400

1. 3/4" exterior grade plywood. 1 sheet enough?

1. West Systems epoxy? How much approx?

2. Biaxial cloth?

3. Drain tube and flanging tool(homeade?)

4. tube of 5200 for through hulls and sealing splashwell. Gas and oil drips a bit from motor so has to be resistant.

5. hardware?

6. Beer

7. ???

Anything else anyone would like to add to make the job go smoother? In the planning stages here obviously. I've ran through some threads and have the general idea of how it's going to go down. The wood in the transom on this thing doesn't go all the way to the bottom of the hull so I'm thinking I'll be able to use 1 4x8 sheet of plywood but I haven't done any measurements yet so I'm not sure. The gas and oil also hastened the rot in the middle of the transom there under the motor. Is this epoxy and 5200 going to stand up to some petroleum products? I'll be more careful than the last guy and wipe it out regularly, but I can't get the motor to stop leaking a bit for some reason. I plan on starting in a week or two and will be posting plenty of pictures!

Under splashwell:

Gas/rot under motor:

1. West Systems epoxy? How much approx?

2. Biaxial cloth?

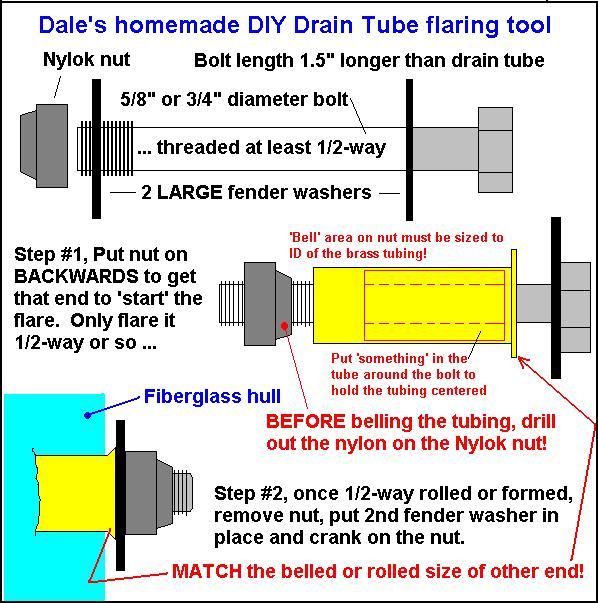

3. Drain tube and flanging tool(homeade?)

4. tube of 5200 for through hulls and sealing splashwell. Gas and oil drips a bit from motor so has to be resistant.

5. hardware?

6. Beer

7. ???

Anything else anyone would like to add to make the job go smoother? In the planning stages here obviously. I've ran through some threads and have the general idea of how it's going to go down. The wood in the transom on this thing doesn't go all the way to the bottom of the hull so I'm thinking I'll be able to use 1 4x8 sheet of plywood but I haven't done any measurements yet so I'm not sure. The gas and oil also hastened the rot in the middle of the transom there under the motor. Is this epoxy and 5200 going to stand up to some petroleum products? I'll be more careful than the last guy and wipe it out regularly, but I can't get the motor to stop leaking a bit for some reason. I plan on starting in a week or two and will be posting plenty of pictures!

Under splashwell:

Gas/rot under motor:

Last edited: