achris

More fish than mountain goat

- Joined

- May 19, 2004

- Messages

- 27,468

I've read a few threads where people are being left stranded when a solenoid on the trim system stops conducting. It can be embarrassing when you can't get the stern drive unit down after launching, or a serious problem if you can't get it up high enough to be safe to trail... I've had it happen to me with my old engine, a couple of times. All I did was drop a screwdriver across the terminals and the trim motor ran the way I wanted it to... But I have had to talk people through, on a mobile phone, who have as much understanding of electricity as an amoeba... Not something you really want to be doing at 6am :facepalm:

So I have come up with a workable solution... It involves a little work up front, but could be a life-saver at the time you need it... I've added a 3 terminal switch to the trim pump bracket, which powers the trim motor without using the solenoids...

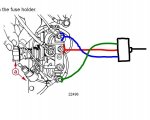

On the standard trim pump mounting bracket there is a hole of just the right size, and in just the right position... I put a 20A momentary switch (ON)-OFF-(ON) in there, and ran the wires up behind the pump motor, a red wire from the positive bus (between the 2 solenoids) to the centre position on the switch, and a green and a blue from the post on the solenoids that each go to the motor. Pushing the switch up runs the drive UP, and down runs it DOWN, bypassing the solenoids.... Should the time come when I get the dreaded 'click', 'click' from the solenoids, I have the emergency bypass in place... I used the same size wire as the motor wires, 6mm, and as the runs are short, less than 300mm, the wires don't get hot....

Here's a photo of the setup on the bracket....

So I have come up with a workable solution... It involves a little work up front, but could be a life-saver at the time you need it... I've added a 3 terminal switch to the trim pump bracket, which powers the trim motor without using the solenoids...

On the standard trim pump mounting bracket there is a hole of just the right size, and in just the right position... I put a 20A momentary switch (ON)-OFF-(ON) in there, and ran the wires up behind the pump motor, a red wire from the positive bus (between the 2 solenoids) to the centre position on the switch, and a green and a blue from the post on the solenoids that each go to the motor. Pushing the switch up runs the drive UP, and down runs it DOWN, bypassing the solenoids.... Should the time come when I get the dreaded 'click', 'click' from the solenoids, I have the emergency bypass in place... I used the same size wire as the motor wires, 6mm, and as the runs are short, less than 300mm, the wires don't get hot....

Here's a photo of the setup on the bracket....

Last edited: