Hi all,

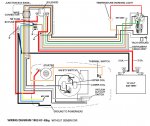

I've never rewired a boat for electric start and lights so I'm wondering couple of things:

1) What are the best connectors to use? Obviously the ignition switch and lights connectors will be predetermined but what about at the connection to the harness from the outboard?

2) Where can I get information about converting the lights to LED from bulb. Is there (I hope) and easy adapter so I don't have to redo all of the lights.

3) What works best as a sheath for the wiring extending from the lights/ignition at the front to the back of the boat to protect the wires from the elements and weather.

4) what gauge and type of wire should I be using?

Thanks!

Rob

I've never rewired a boat for electric start and lights so I'm wondering couple of things:

1) What are the best connectors to use? Obviously the ignition switch and lights connectors will be predetermined but what about at the connection to the harness from the outboard?

2) Where can I get information about converting the lights to LED from bulb. Is there (I hope) and easy adapter so I don't have to redo all of the lights.

3) What works best as a sheath for the wiring extending from the lights/ignition at the front to the back of the boat to protect the wires from the elements and weather.

4) what gauge and type of wire should I be using?

Thanks!

Rob