AShipShow

Lieutenant Commander

- Joined

- Jul 8, 2016

- Messages

- 1,803

Hello all,

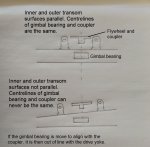

I'm trying to align my 1996 mercruiser 5.7L with alpha 1 gen 2 after a full restoration. Everything with the transom was in spec after the rebuild... i seem to be getting heavier spline marks on the starboard side of the alignment tool... my first instinct was to rotate the engine... I spun it 180 degrees and it's still heavy on the starboard side so I assume bent coupler is ruled out...

My only guess at this point is the front mounts are out of the correct location...

Are there any other possibilities that could cause this?

Last night I loosened the rear mounts and removed the lag screws from the front mounts and lifted it by the thermostat housing lift point and the port side front mount was a little off once the motor centered itself and the starboard side mount was pretty close... doesnt quite seem enough to be the issue... hoping it is but want to make sure I'm not missing something before I remove the engine, fill, and redrill the front mounts...

Thanks

I'm trying to align my 1996 mercruiser 5.7L with alpha 1 gen 2 after a full restoration. Everything with the transom was in spec after the rebuild... i seem to be getting heavier spline marks on the starboard side of the alignment tool... my first instinct was to rotate the engine... I spun it 180 degrees and it's still heavy on the starboard side so I assume bent coupler is ruled out...

My only guess at this point is the front mounts are out of the correct location...

Are there any other possibilities that could cause this?

Last night I loosened the rear mounts and removed the lag screws from the front mounts and lifted it by the thermostat housing lift point and the port side front mount was a little off once the motor centered itself and the starboard side mount was pretty close... doesnt quite seem enough to be the issue... hoping it is but want to make sure I'm not missing something before I remove the engine, fill, and redrill the front mounts...

Thanks