Hi,

Trying to bring this motor back to use and could use some help.

Model 6802R.

Compression 140/138.

Checked points to 0.02 and then when it was running I checked with strobe light. It stays perfectly between two marks on both cyls.

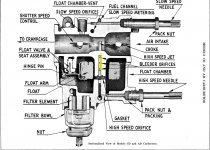

Disassembled and cleaned carb. Opened low speed needle to 1&1/4 turn and high speed needle to 3/4 turn as per manual.

It had 18HP fuel pump, so I replaced it with new original just to exclude it from equation.

New spark plugs.

Starts right away cold and runs smooth and steady around START mark on tiller handle. Left it for 30 mins, no issues.

Problems begin when I turn the tiller handle:

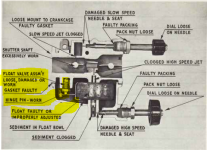

1. If I go to FAST it does not speed up. Just stays the same. Only if I start to close high speed needle it speeds up. The max rpms is with completely closed HS needle.

2. If I turn from START to SLOW it does speed up ( instead of slowing down), but then stops .

Also, after it stops like that it is kind of hard to start again, but when starts, runs fine again.

Playing with speed needles did not do much, except above note for HS needle.

It is very simple basic motor and with all components in good condition it should not be very difficult to set.

What am I missing?

Any ideas?

Thanks.

Trying to bring this motor back to use and could use some help.

Model 6802R.

Compression 140/138.

Checked points to 0.02 and then when it was running I checked with strobe light. It stays perfectly between two marks on both cyls.

Disassembled and cleaned carb. Opened low speed needle to 1&1/4 turn and high speed needle to 3/4 turn as per manual.

It had 18HP fuel pump, so I replaced it with new original just to exclude it from equation.

New spark plugs.

Starts right away cold and runs smooth and steady around START mark on tiller handle. Left it for 30 mins, no issues.

Problems begin when I turn the tiller handle:

1. If I go to FAST it does not speed up. Just stays the same. Only if I start to close high speed needle it speeds up. The max rpms is with completely closed HS needle.

2. If I turn from START to SLOW it does speed up ( instead of slowing down), but then stops .

Also, after it stops like that it is kind of hard to start again, but when starts, runs fine again.

Playing with speed needles did not do much, except above note for HS needle.

It is very simple basic motor and with all components in good condition it should not be very difficult to set.

What am I missing?

Any ideas?

Thanks.