You’re welcome, happy to help when I can.

I’m not aware of ignition bypass on any Volvo EGC engine. Yours doesn’t have it.

I have some concerns about using the Jaltest software. It hasn’t received Volvo Penta approval here in North America. I’m pretty sure your engine should be outputting codes in the SPN/FMI format. But I understand that a person needs to work with what they have available. Are you seeing any freeze frame data with the fault codes? Are they listed as “active” or “previously active”?

I don’t know why the engine will run with the CMP disconnected. You should only get spark for about 4 revolutions and then no spark/fuel. There is no limp mode on this engine. The only strategy available is power derate, that should limit RPMs to about 2500. But you maybe able to use this to watch the scan tool for any “shifting” sensor values.

I have a couple of reasons for recommending repairing your 2 fault codes before more troubleshooting. First is that this is what any trained technician will do unless they are 100% sure the codes will have no effect, and it’s what all the factories recommend. Second is because I’ve been burned by this before. An open warning buzzer can cause a “small” derate to become a “big” derate. When I asked Tech support why this isn’t listed in any of the diagnostic manuals? I was told that sometimes this strategy is included in the software to try to protect the engine from a customer that is unaware there is a problem. Also “you didn’t hear the buzzer during key on, why did you start the engine without correcting a known problem?” I don’t know if your ECM has this programming.

The trim code can cause this on some products. The ECM will not allow the engine to start if it is trimmed up too far. I’ve never seen this on a product as old as yours, just newer outboards. But it is another example of the manufacture trying to save their engine from unaware operators. Also don’t worry about the trim code if you don’t have an analog trim gauge.

While we are on the subject of trim, read this and if you don’t have the 120 Ohm resistor. I recommend you contact your Volvo dealer and order the kit to add it.

Mid-year of the –J model engines, a 120 Ohm resistor was added to the engine

harness in the 5V Ref #1 circuit leg feeding the trim sensor. This resistor was added to

protect the 5V Ref #1 circuit from being shorted to ground by a faulty trim sensor. It

looks like a 2 wire connector and is taped to the engine harness near the fuse box. If

the trim sensor shorts the 5VRef #1 to ground on engines that don’t have this resistor,

the engine will shutdown due to loss of the CKP and CMP sensors.

Is this the procedure you used when checking the CMP?

The only good method for validating CMP input is to: 1st). Disconnect the CMP sensor

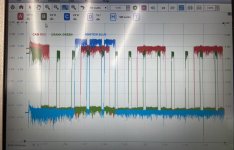

connector and measure the 5V reference 1 voltage to a good ground (ground stud). 2nd). Ensure that there is the same voltage between the 5V reference 1 and sensor return #1 at the CMP connector. 3rd). Check the signal wire and ensure that it has continuity from one end to the other and is not shorted to any ground (power ground, sensor return #1 or sensor return #2). 4th). Then check for a CMP signal at the ECM (pin 23) with either an Oscilloscope, a DC Hertz meter or a good AC voltmeter while cranking the engine with the CKP (crankshaft position) sensor disconnected. Having the CKP sensor disconnected prevents the ECM from firing any ignition coils and any fuel injectors.

I would be interest to know if the distributor has ever been moved on this engine? Is Cam Retard reading between 12° - 15°?

I too am old enough to remember to days of mechanical fuel injection. I still have the tape measure Deutz Diesel gave me to time their engines. Did you know that some of their engines didn’t have a head gasket? Those darn Germans were that good at machining the block and head they didn’t need one!

But I also remember the stink and poor fuel economy, the fuel sheen on the water and the CO that they produced. I don’t miss that or the pollution.

I totally get the people that wish for the “good old days” but I like the indoor plumbing and the reliable engines modern technology has given us.

People like to complain about the new engines with catalytic converters on them. But those engines are happy to tell me what cylinder has the misfire. All I need to do is ask.

You don’t mention what troubleshooting you have done so far. Have you done the basics? Compression, fuel pressure and visual inspection?

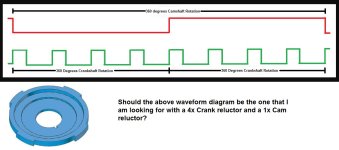

EDIT: after reading this, most of my books list this engine as having an 24X reluctor on the crank. But this engine being near the end of the non cat engines I don't know for sure. Either way I wouldn't be worried about it being to close to the reluctor, never heard that to be a problem.

And remember the ECM must see at least 4 revolutions to set a code.