not having the specs on the 1999 5psi seems....very low.

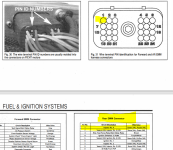

the book on 70hp says minimum 34 psi so the 155hp should certainly have more than 5psi ... to pressurize try a few key on 3-4 and test fuel pressure.

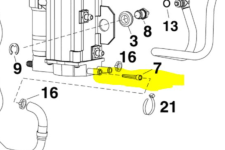

View attachment 378300

the lift pump can be simulated by hand pumping I doubt it is the issue

in any event if you hand pump and the VST does not fill up there may be a blockage .

have you checked the VST return filter to see if you have one first of all and is it packed with crud enouh to mess up fuel circulation ?

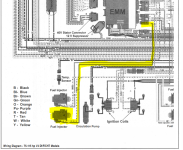

test the HP pump by applying voltage. it should spin and bring up the PSI to norm whatever that is on athe 1999 FICHT

VST is just a can to cool fuel and vent air/fuel fumes

btw found a post where 40 volts was the expected voltage with engine running...? odd

you have EV Diagnostics... any fault codes active ??