Re: 1956 Evinrude Fleetwin freshen-up *conclusion*

Re: 1956 Evinrude Fleetwin freshen-up *conclusion*

The seal was easily crushed, and pulled out after this.

Just a note for anybody trying this method to remove their seal; Go very shallow when you're drilling. The shell of this seal gets pierced in no time with a good sharp drill bit. You may not even know you're completely through the seal and into the housing. I had a couple of spots where I actually drilled into the housing, but the damage was more or less superficial.

So with the old seal removed, time to pop in my new seal, right?

Wrong!!! As you will notice, there is a gap between my new seal and that housing. WTH? Then it dawned on me... Remember how I said this casting was heavier then the one I had before? This must be the superseded bearing housing that I had found out about when I was in search for a replacement bearing housing (OMC P/N 382796).

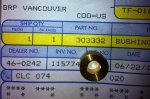

For grins, I went on shop.evinrude.com, clicked on the 1968 motors (oldest that BRP lists), and looked at the lower gear case section for a 6HP engine (I figured this would be the engine that may be closest to mine). Sure enough, that bearing housing was the same part number as my new friend. And my new friend used a different part number seal for the drive shaft.

For the record, '68 was a split year for that bearing housing. Some of the 6 horses used the older housing, others used the newer style with the different seal. Keep this in mind when looking stuff up, as the Sierra catalog has notations. For a safe way to locate this, if you have a newer style housing, you need a shaft seal that would be used from '69 on. Or you can just use the part numbers I give ya below...

OMC part number 314167 (or Sierra 18-2024) is the shaft seal that matches with the newer 382796 housing.

If you have the old housing number 376074, the seal you want was originally OMC 300599, but has been superseded to BRP 327031, or Sierra 18-2035.

OK, so now I know that newer style housing uses a different seal, where do I find one? First stop was NAPA with the Sierra part number for that seal. The parts dude looked up the availability of it, and said the nearest one was in Illinois, and would take a week to get. Since I wasn't going to be still in Maine in a week, and I wanted to get this motor together, I decided to locate a few Evinrude dealers. First place I went to was in the back woods. Nice folks there, but didn't seem too interested in ordering my seal, and gave me the same line about how long it would take for them to get a Sierra seal, or an entire seal kit for that newer style lower. I looked up more dealers at Evinrudes website, and got a number for one in Portland ME. I called them, and rattled off the OMC/BRP part number for the seal I needed. The nice lady said she didn't have it, but could have it for my by Friday. Perfect, order it up honey!

This is the new seal;

Just so you can see the difference, here is the old (smaller) seal compared to the new seal;

So with the seal in hand, my Maine neighbor/friend helping out where additional hands were needed, and pleanty of 847, we got the lower all back together. Ain't she sweet;

Best of all, she doesn't leak a drop of oil either!