Faztbullet

Supreme Mariner

- Joined

- Mar 2, 2008

- Messages

- 15,937

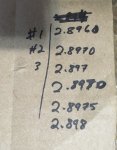

1) .006 is wrong and .003 is correct. Anything over.003 of factory finished bore sizes is worn. If "Wayne" bored correctly the bore will measure 2.890 as piston skirt will mike 2.887 +/- .0005

2) Nope as bore way past wear limit spec,, will have piston slap..Pro Marine even told ya so.

3) Certified Merc/Mariner /Mercruiser Tech thru Mercury Marine, business owner, build an raced I-6 motors, had Kwik way boring bar and bored blocks, wrenching on Mercs since 1977

2) Nope as bore way past wear limit spec,, will have piston slap..Pro Marine even told ya so.

3) Certified Merc/Mariner /Mercruiser Tech thru Mercury Marine, business owner, build an raced I-6 motors, had Kwik way boring bar and bored blocks, wrenching on Mercs since 1977