Here are my key questions with supporting pictures. Your responses are my commands.

The questions hinge on the port and starboard in this first photo where the decking was once mounted. (SeaRay must own PL because they spread that stuff around quite generously. A good thing I guess until you learn that wood in boats won't outlast it!)

The first close ups show the port side where I ground the former mounting place fairly well - blending the sideward extra fiberglass matting (pretty thick too) that once held the decking in place (an assumption), construction adhesive, and bottom hull areas. The next close-up is the mounting place on the starboard side of this photo. I didn't take time to "blend" via grinding because I wondered if:

1) Can I leave some of this construction adhesive in place or must it all go? It is solidly attached to the hull, doesn't absorb water, and adds some rigidity. I left no original wood behind. Easy to do on this boat!

2) If you say take it out, which as you are probably already aware, will result in plenty more grinding time and will remove some original thick fiberglass that once held the top side of the decking in place. (Maybe it was originally put there for strength and had nothing to do with holding down the decking. When I say thick, it's over 1/8" thick.) Why would it need to all come out when it will be under the floor boards, which will be covered in resin and some type of glass cloth, with either peanut butter or PL on top of both old construction adhesive and hull? Also, the expanding foam will likely fill any gaps near the underside edges of the floor boards. Just trying to align energy and time with purpose.

3) If you say it's OK to leave original well-adhered construction adhesive in place, how important is it that I blend the three (thicker fiberglass at the side, construction adhesive, and the hull) into a smooth sloping plane when it will be under the decking?

Here is a close up of the port side. I ground this side so-as-to to blend materials into a smooth slope. I'll be sanding with 36grit to remove air pickets and ridges.

Here is a closeup or the starboard side (I didn't grind this one to a " sloping blend"). It's rough looking but does it matter?

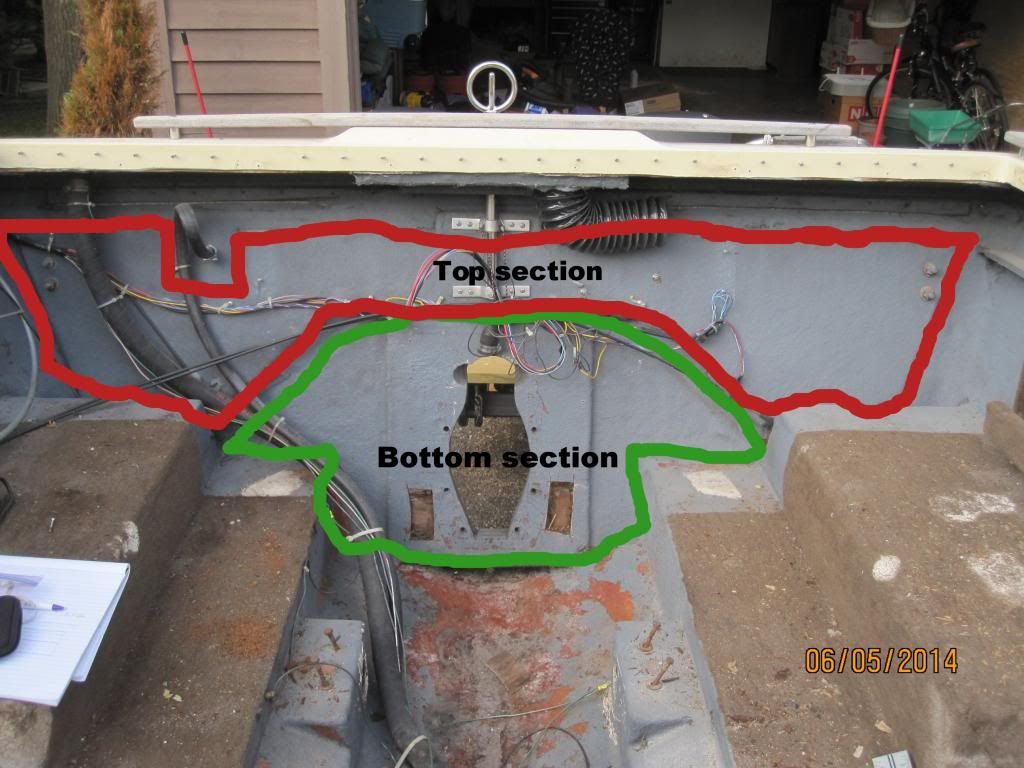

And one more perspective for the same question. This time from the area where some useless structure was in base of the ski locker. Maybe it was there for centerline strength. I'll be putting it back during rebuild because I'm certainly no boat engineer! (Do I really need to grind away all construction adhesive here too?)

I guess the question also applies to the construction adhesive where the stringers attached as well. You can see it in this photo as well. Does 100% of it have to go? Even where it is filling a strake?