greenstripe

Cadet

- Joined

- Sep 30, 2021

- Messages

- 7

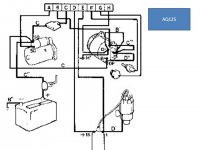

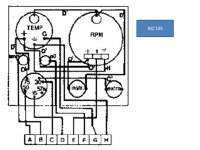

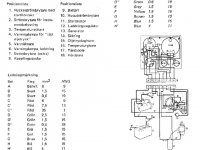

I have a Brown wire exiting the wiring harness at engine compartment and am not sure if the wire goes to ignition coil terminal or alternator. The brown wire is connected to either a fusible link or a resistor and I am afraid to short anything out. The Bosch distributor has new Pertronix electronic ignition, but the problem is the engine only seems to crank but no spark. I need to find out where the brown wire needs to be connected to. I do have the manual, but am still unsure. Any advise is greatly appreciated.