BWR1953

Admiral

- Joined

- Jan 23, 2009

- Messages

- 6,525

1992 Merc XR6 150hp

I've added all new Faria engine gauges in my boat after a successful splash back in May. It takes me a (very) long time to get anything done, but I've been poking along.

The gauges are all installed and wired up to power and ground.

This morning I went out to connect and test the tilt/trim sender, temp sender and water pressure loss warning light. I plan to add a beeper/buzzer for the pressure loss indicator light too.

1. When the engine was installed last year, the brown/white wire for the tilt sender was cut to allow moving the engine from the donor boat to this one. Today I tightly twisted the 2 brown/white wire ends together and tested. No joy. When powered off, the gauge is about full up. When I switched power on, it drops to full down. However, when I raised/lowered the engine, the gauge only twitched, but didn't move up or down.

I can't find where the sender is located.

2. I connected the temp gauge to the tan wire and when it powered up, the gauge went to full hot. I don't know if that's normal or not, but it seems backwards to me. I haven't tried running the engine yet though.

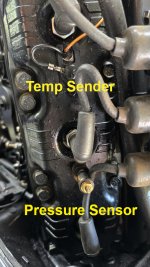

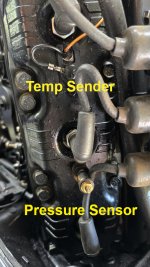

3. I connected the pressure loss tan/blue wire to the warning light and it came on dimly. But! I think it wasn't connected to the sensor. I tried jumping from the sensor to the gauge and got nothing. Disregard the spark plug wire. I just moved it out of the way for the pic. It doesn't touch anything.

So, that's where I am now. I have a Service Manual and will be checking that, but so far no joy. Any ideas?

I've added all new Faria engine gauges in my boat after a successful splash back in May. It takes me a (very) long time to get anything done, but I've been poking along.

The gauges are all installed and wired up to power and ground.

This morning I went out to connect and test the tilt/trim sender, temp sender and water pressure loss warning light. I plan to add a beeper/buzzer for the pressure loss indicator light too.

1. When the engine was installed last year, the brown/white wire for the tilt sender was cut to allow moving the engine from the donor boat to this one. Today I tightly twisted the 2 brown/white wire ends together and tested. No joy. When powered off, the gauge is about full up. When I switched power on, it drops to full down. However, when I raised/lowered the engine, the gauge only twitched, but didn't move up or down.

I can't find where the sender is located.

2. I connected the temp gauge to the tan wire and when it powered up, the gauge went to full hot. I don't know if that's normal or not, but it seems backwards to me. I haven't tried running the engine yet though.

3. I connected the pressure loss tan/blue wire to the warning light and it came on dimly. But! I think it wasn't connected to the sensor. I tried jumping from the sensor to the gauge and got nothing. Disregard the spark plug wire. I just moved it out of the way for the pic. It doesn't touch anything.

So, that's where I am now. I have a Service Manual and will be checking that, but so far no joy. Any ideas?