cjslapshot

Recruit

- Joined

- May 1, 2015

- Messages

- 4

I just posted a new topic a few hours ago but I don't know what happened to it so her it goes again.

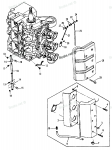

1994 Force 90hp Outboard. Runs great but I found that there is a small fitting on the bottom of the plastic intake cover. The intake cover collects the fuel that spills out from the carbs when the engine is tilted. My fitting is not connected to anything and I am a little confused when it comes to where the fuel is supposed to go. Currently the fuel just leaks out into the cowling. I have attached a diagram below. The fitting that is on the intake is part "7". The line "9" is missing but I can get that in any parts store. What I'm worried about is part "10". This is a fitting with a "metering cup". Is it just a check valve? Where does this part go back into the motor? How is the fuel recirculated? A pump? Vacuum? I'm concerned with fuel coming back into the intake and air getting into the fuel system. I'm surprised that the engine runs great without this part in place. Any info would be greatly appreciated.

1994 Force 90hp Outboard. Runs great but I found that there is a small fitting on the bottom of the plastic intake cover. The intake cover collects the fuel that spills out from the carbs when the engine is tilted. My fitting is not connected to anything and I am a little confused when it comes to where the fuel is supposed to go. Currently the fuel just leaks out into the cowling. I have attached a diagram below. The fitting that is on the intake is part "7". The line "9" is missing but I can get that in any parts store. What I'm worried about is part "10". This is a fitting with a "metering cup". Is it just a check valve? Where does this part go back into the motor? How is the fuel recirculated? A pump? Vacuum? I'm concerned with fuel coming back into the intake and air getting into the fuel system. I'm surprised that the engine runs great without this part in place. Any info would be greatly appreciated.

Attachments

Last edited: