SparkieBoat

Captain

- Joined

- Aug 17, 2009

- Messages

- 3,643

Re: 1995 J200 stalls above idle

here is how to test regulator..you do not need the things you mentioned.

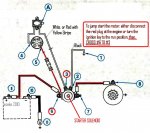

Testing regulator/rectifiers on the engine

Recommended tools:

Fluke multimeter with DVA adapter (CDI 511-9773-NL) Piercing probes (CDI 511-9770)

Ammeter Adapter (CDI 511-9772)

Battery Load bank

1. Check the purple wire for voltage while the engine is running. You should see the same voltage as the battery.

2. With all wires connected and the engine running at approximately 1500 RPM, check the DVA voltage from each yellow wire to

engine ground. The two readings have to be within 2 volts of each other (i.e. if one is reading 20 volts, the other has to read

between 18 and 22 volts). If the readings are not equal, go to step 3. If they are equal, go to step 2.

3. Check the DVA voltage from the yellow wires to the red wire going to the solenoid. The two readings must be within 2 volts of each

other. If the readings are unequal, replace the rectifier/regulator. If they are equal on this step and step 1, the rectifier (or

rectifier/regulator) and battery charging portion of the stator are OK.

4. If the readings are unequal, mark across the connection between the stator and rectifier on the low side. Turn the engine off and

swap the stator leads. Crank the engine up and retest. The component that has the marked wire with the low reading is bad.

5. At 800-1000 RPM, check output on the gray wire, reading should be at least 8 volts with a DVA meter. A low reading usually

indicates a bad regulator if the system is charging the battery.

download the install sheet from this page for more info

http://www.cdielectronics.com/AppGuide.aspx?Criteria=0584641

here is how to test regulator..you do not need the things you mentioned.

Testing regulator/rectifiers on the engine

Recommended tools:

Fluke multimeter with DVA adapter (CDI 511-9773-NL) Piercing probes (CDI 511-9770)

Ammeter Adapter (CDI 511-9772)

Battery Load bank

1. Check the purple wire for voltage while the engine is running. You should see the same voltage as the battery.

2. With all wires connected and the engine running at approximately 1500 RPM, check the DVA voltage from each yellow wire to

engine ground. The two readings have to be within 2 volts of each other (i.e. if one is reading 20 volts, the other has to read

between 18 and 22 volts). If the readings are not equal, go to step 3. If they are equal, go to step 2.

3. Check the DVA voltage from the yellow wires to the red wire going to the solenoid. The two readings must be within 2 volts of each

other. If the readings are unequal, replace the rectifier/regulator. If they are equal on this step and step 1, the rectifier (or

rectifier/regulator) and battery charging portion of the stator are OK.

4. If the readings are unequal, mark across the connection between the stator and rectifier on the low side. Turn the engine off and

swap the stator leads. Crank the engine up and retest. The component that has the marked wire with the low reading is bad.

5. At 800-1000 RPM, check output on the gray wire, reading should be at least 8 volts with a DVA meter. A low reading usually

indicates a bad regulator if the system is charging the battery.

download the install sheet from this page for more info

http://www.cdielectronics.com/AppGuide.aspx?Criteria=0584641