Re: 1999 Celebrity 190 - Engine Mount and Stringer Repair

Now it's time for some questions I've been meaning to ask:

1) What grit of sandpaper is recommended for buzzing down the bare plywood before wetting it out?

2) After finish up the 1708 on the stringers and bulkheads, I came back the next day and noticed some air pockets in a couple of places along the fillets. A couple on the order of 1-2" long by 3/4" high. Not sure if they were there when I did my primary tabbing of CSM or if the bubbles are between the CSM and 1708. Should I grind those areas down and redo, or drill a small hole and inject resin, or don't worry about it and do nothing? Here are some examples.

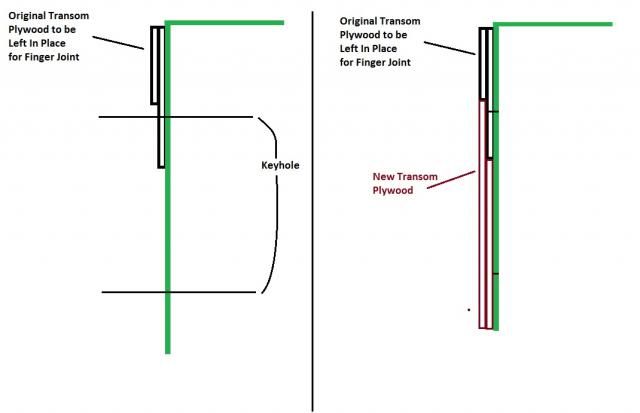

3) If you'll remember my plan to redo the transom (back in post #63), basically was going to fully remove the centre section, leaving outer wings of the existing transom. I'm still forging ahead with this plan but may do a slight modification to it. Here is the issue. On the top of the transom, I have very little to no room between it and the top cap to tab the new transom to existing hull glass above the outdrive. I was thinking of leaving a 4"-6" strip at the top of the original centre section in place, and to a ruff'n'scuff on the glass, this would give me a strip of

something to tab in my new transom to something existing. Essentially, when the new transom is in place, it would sit flush with the old strip directly above it, then I can 1708 over the entire thing. Then I got thinking, rather than cut right down to the hull glass at that strip, why not only cut down 3/4" and leave another 4" strip of original transom plywood just below it. That way I could finger joint the new transom in with the existing one for better strength, this is difficult to explain, not sure if the following will illustrate, may need to do a profile drawing.